By Ajay Bhoyar, Senior Global Technical Manager, EW Nutrition

Gut health is pivotal to profitable poultry production, as the gastrointestinal tract (GIT) enables nutrient digestion and absorption while acting as a defense against pathogens. A healthy gut improves feed conversion, boosts immune resilience, and reduces reliance on antimicrobials—critical in the fight against antimicrobial resistance (AMR). With AMR posing significant threats to public health and animal agriculture, strategies like biosecurity, sustainable management, and effective dietary interventions are gaining traction. Feed enzymes have emerged as essential tools for managing feed costs, mitigating anti-nutritional factors, and improving nutrient utilization. Among these, feed enzymes like xylanase stand out. By breaking down xylan, a major component of non-starch polysaccharides (NSPs) in plant-based feed ingredients, xylanase reduces gut viscosity, enhances nutrient utilization, and supports optimal gut health and productivity. This article explores the innovative application of novel GH10 xylanases, such as Axxess XY, as a sustainable solution for improving feed efficiency and gut health in poultry production.

Xylanase in Poultry Nutrition

Xylanase plays a pivotal role in enhancing nutrient availability by addressing the limitations of endogenous enzyme synthesis in poultry. Xylanase enzymes belong to the carbohydrase class, catalyzing the breakdown of xylan, a major NSP in plant-based feed ingredients. They hydrolyze xylan into simple sugars like arabino-xylo-oligosaccharides (AXOs) and xylo-oligosaccharides (XOs), reducing the encapsulation of nutrients and digesta viscosity. These actions improve overall nutrient digestibility and bird performance.

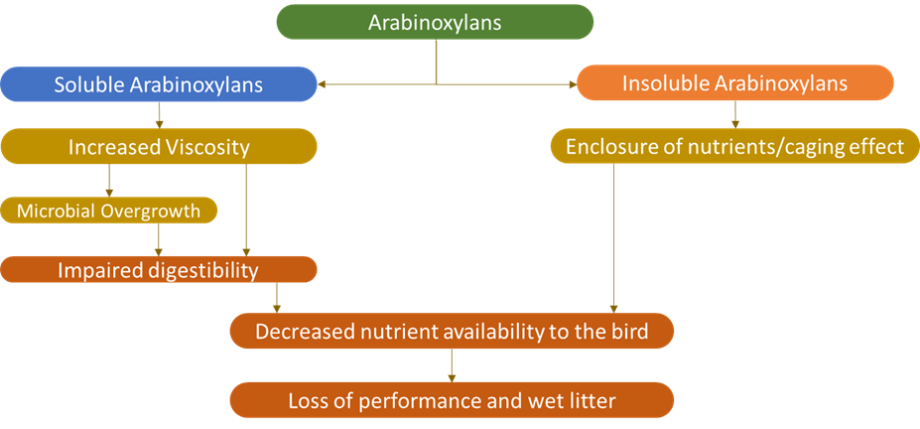

Fig.1: Arabinoxylans – anti-nutrient mode of action in chicken

The primary benefit of feed xylanase lies in its ability to reduce digesta viscosity. By partially hydrolyzing NSPs in the upper digestive tract, xylanase ensures better nutrient absorption in the small intestine. Studies (Matthiesen et al., 2021; Choct & Annison, 1992) confirm that reduced viscosity enhances feed digestibility, leading to improved performance in poultry. Further, to realize the optimum benefits, it is crucial that xylanase efficiently degrades both soluble and insoluble arabinoxylans. The insoluble arabinoxylans are part of the cell wall structure of plant cells, resulting in a cage effect, entrapping nutrients like starch and protein. Effectively breaking down insoluble arabinoxylans ensures that the nutrients trapped in plant cell walls are released for growth and production.

Mechanisms Supporting Gut Health

Viscosity Reduction

High NSP content increases digesta viscosity and slows digestion and nutrient absorption. Soluble arabinoxylan is not digested in the small intestine of broilers. It produces a viscous chime, leading to the proliferation of pathogenic bacteria, intestinal inflammation, impairment of barrier function in the intestine, and severe intestinal lesions (Teirlynck et al., 2009). Xylanase mitigates this by breaking down xylans, a major component of NSPs in common feed ingredients. This results in a better flow of digesta and reduced energy losses.

Microbial Metabolites

Xylo-oligosaccharides (XOS) can also be produced in the intestine of monogastric animals to some extent when exogenous enzymes, such as xylanase, are added to the feed (Baker et al., 2021).

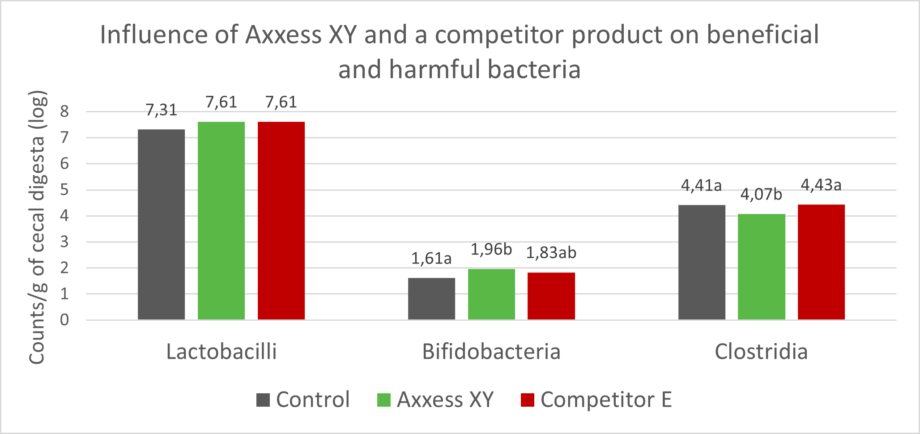

The XOS generated by xylanase action on arabinoxylans can act as prebiotics, fostering beneficial bacteria like Lactobacillus and Bifidobacterium, which can outcompete harmful species. XOS can positively impact the gut microbiota, enhance short-chain fatty acid (SCFA) production, stimulate immune activity in the gastrointestinal tract, and improve energy utilization.

Fig. 2. Axxess XY improved beneficial microbes and reduced the clostridial population in broilers.

Barrier Function

By lowering inflammation and irritation in the intestine, xylanase helps maintain gut integrity, reducing the risk of pathogen translocation from the intestinal lumen. In a broiler study, xylanase decreases epithelial apoptosis index, up-regulates tight junction gene expression, and inhibits mucin synthesis in the small intestine, likewise alleviating the intestinal mucosal barrier impairment from Clostridium perfringens challenge (Liu et al., 2012).

Practical Considerations for Xylanase Use

Enzyme Stability

Enzymes are proteins that tend to lose their catalytic activity at high temperatures. When exposed to excessive heat, an enzyme’s protein structure can irreversibly unfold, disrupting its active site and causing loss of function. Therefore, ensuring enzyme stability during feed processing is critical for maintaining its activity in the intestine. Intrinsically heat-stable enzymes have an inherent ability to withstand higher temperatures without the need for a protective coating and are immediately available for action upon ingestion.

Feed Composition

Xylanase efficacy is influenced by diet composition, particularly the NSP content and the presence of xylanase inhibitors in common feedstuffs. It is important to choose a xylanase that can resist the activity of xylanase inhibitors and is effective against both soluble and insoluble arabinoxylans.

The recommended energy matrix value for the xylanase enzyme should be used while formulating the feeds to create energy-deficient diets to reap the full benefits of xylanase use.

Optimal Dosage

Proper dosing is essential to maximizing the benefits of feed enzymes while avoiding unnecessary costs. It is important to follow manufacturers’ recommendations and avoid underdosing an enzyme.

GH10 Xylanases: The Superior Choice for Animal Nutrition

Most feed xylanases are classified into glycoside hydrolase families 10 (GH10) and 11 (GH11) based on their substrate specificity, catalytic action, and structural features.

Why GH10 Xylanases Are More Effective

-

Broader Substrate Specificity:

Unlike GH11 xylanases, GH10 xylanases can effectively hydrolyze both soluble and insoluble xylan substrates. This broader activity ensures an efficient breakdown of xylans in a wide range of feed ingredients.

-

Higher Catalytic Efficiency:

GH10 enzymes cleave xylan at substituted regions, yielding shorter xylo-oligosaccharides that can positively impact gut health and maximize nutrient availability.

-

Thermostability:

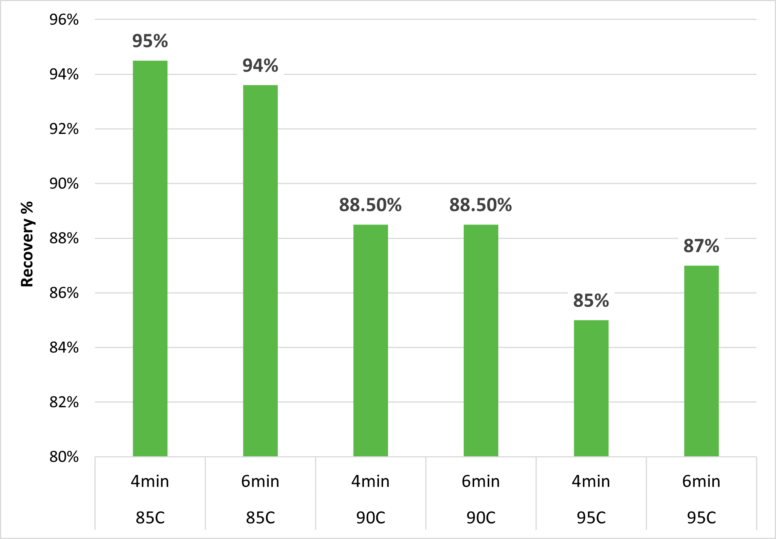

Feed processing often involves high temperatures during pelleting. Axxess XY, a GH10 family xylanase, demonstrates remarkable thermostability, maintaining over 85% activity even at 95°C for extended conditioning times. This resilience ensures consistent enzyme performance during feed manufacturing and digestion.

Fig.3: Optimum recovery of Axxess XY at elevated conditioning time and temperatures

Novel Applications of Axxess XY: A GH10 Xylanase

Axxess XY exemplifies the advantages of GH10 xylanases in poultry nutrition. Its ability to efficiently act on both soluble and insoluble arabinoxylans makes it a versatile feed enzyme. The enzyme’s high thermostability ensures efficient enzyme activity in the gut and subsequent optimum nutrient utilization under challenging processing conditions, promoting gut health and maximizing performance.

Key Benefits of Axxess XY

-

Enhanced Nutrient Utilization:

By unlocking nutrients trapped in NSPs, Axxess XY promotes better feed conversion ratios (FCRs).

-

Improved Gut Health:

Reducing the digest’s viscosity reduces gut health challenges and predisposition to gut infections. Further, the short-chain oligosaccharides released by Axxess XY support beneficial gut microbiota, improving digestive health.

-

Economic Efficiency:

Enabling the optimum use of high-fiber, cost-effective, locally available feed ingredients without compromising performance makes Axxess XY an asset for profitability.

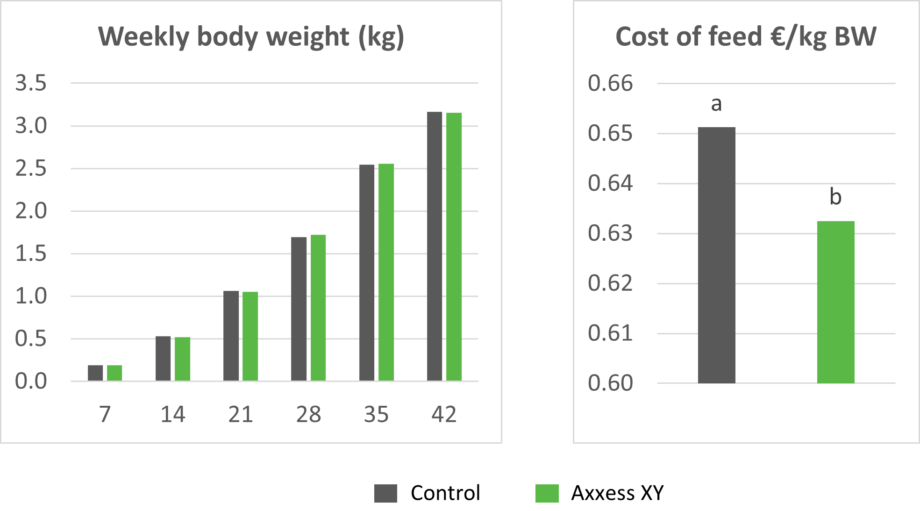

In a recently conducted 42-day trial at a commercial farm, Axxess XY maintained the average body weight of broilers with a 100 kcal/kg reduction in metabolizable energy while significantly reducing feed cost/kg body weight. The diets were based on corn, DDGS, and soybean meal.

Figures 4 and 5: Body weight and cost of feed in broilers fed a diet reduced by 100 kcal/kg in metabolizable energy compared to a standard diet without Axxess XY

Conclusion

Xylanase exemplifies how feed enzymes can transcend their traditional role in feed cost reduction to support enhanced gut health. Xylanase supports reduced antimicrobial use in poultry production by improving nutrient utilization, reducing digesta viscosity, and fostering healthy microbiota. Its integration into comprehensive gut health management strategies offers a sustainable pathway to combat AMR and ensure the long-term viability of poultry farming. By targeting NSPs, these enzymes enhance nutrient digestibility, reduce feed costs, and support sustainable production practices.

GH10 xylanases, particularly Axxess XY, stand out for their superior substrate specificity, catalytic efficiency, and thermostability. By incorporating Axxess XY into feed formulations, poultry producers can unlock the full nutritional potential of feed ingredients, ensuring optimal performance and profitability. As the poultry industry continues to evolve, adopting advanced enzyme technologies like Axxess XY represents a strategic step toward sustainable and efficient animal nutrition.

References:

Baker, J.T.; Duarte, M.E.; Holanda, D.M.; Kim, S.W. Friend or Foe? Impacts of Dietary Xylans, Xylooligosaccharides, and Xylanases on Intestinal Health and Growth Performance of Monogastric Animals. Animals 2021, 11, 609.

Choct, M., and G. Annison. “Anti‐nutritive Effect of Wheat Pentosans in Broiler Chickens: Roles of Viscosity and Gut Microflora.” British Poultry Science 33, no. 4 (September 1992): 821–34. https://doi.org/10.1080/00071669208417524.

Liu D, Guo S, Guo Y. Xylanase supplementation to a wheat-based diet alleviated the intestinal mucosal barrier impairment of broiler chickens challenged by Clostridium perfringens. Avian Pathol. 2012;41(3):291-8.

Matthiesen, Connie F., Dan Pettersson, Adam Smith, Ninfa R. Pedersen, and Adam. C. Storm. “Exogenous Xylanase Improves Broiler Production Efficiency by Increasing Proximal Small Intestine Digestion of Crude Protein and Starch in Wheat-Based Diets of Various Viscosities.” Animal Feed Science and Technology 272 (February 2021): 114739. https://doi.org/10.1016/j.anifeedsci.2020.114739.

Teirlynck, E.; Haesebrouck, F.; Pasmans, F.; Dewulf, J.; Ducatelle, R.; van Immerseel, F. The cereal type in feed influences Salmonella enteritidis colonization in broilers. Poult. Sci. 2009, 88, 2108–2112.