By Marisabel Caballero, Global Technical Manager Poultry, and Dr. Inge Heinzl, Editor, EW Nutrition

Consistently rising feed prices compel feed producers to resort to alternative feed ingredients. By-products of milling and ethanol distillation would be good options. The following article shows what should be paid attention to when using these feeds.

Keeping high-quality animal protein affordable requires cost-efficient alternatives

For a high percentage of consumers, the price of food products is one of the most decisive purchase factors; however, quality and sustainable use of resources are also of high importance. So, to comply with market requirements, meat producers must find cost-efficient and sustainable sources of feed ingredients. Feed prices already increased during the COVID-19 pandemic. Shortage of workforce and high shipping costs led to discontinuity in the supply chain, long delivery times, and increased costs for certain raw materials. Due to the Ukrainian crisis, there is no improvement to be seen. Alternatives must be considered more vigorously to compensate for this limited feed supply.

Grain by-products are an option

The use of grain by-products occurring at milling or ethanol production can cover a part of animal nutritional demands. Additionally, it contributes to sustainable usage of the available sources, as the remains of the production of human consumables are put back into the food chain.

However, increasing levels of by-products in the feed also have their sticking points. The raw materials grains or corn are often contaminated with mycotoxins, impacting the quality of this kind of feed.

Milling processes reduce mycotoxins in food

Before the whole process of milling, the grains are sorted and cleaned. Kernels with extensive mold growth, broken kernels, fine materials, and dust are removed.

When it comes to reducing mycotoxins by sorting and cleaning, the results vary a lot. They are influenced by several factors, including the initial condition of the grains, the type and level of contamination, and the type and efficiency of the cleaning process (Pinotti et al., 2016). The cleaning process has been shown to remove from 5 to 80 % of DON and NIV, 5 to 40 % of ZON (Schaarschmidt & Fauhl-Hassek, 2018), and 50 to 60 % of T2/HT2 contamination in wheat (Pascale et al., 2011). Debranning, the mechanical process by which the outer layers of wheat grains are removed, further reduces mycotoxin content in wheat grain from 15 to 80% of the initial contamination (Aureli et al., 2007; Rios et al., 2009). However, neither the cleaning and debranning nor the milling process include a step that destroys mycotoxins.

In white flour for human consumption, mycotoxin levels typically range from 50 to 70% of the wheat grain (Cheli et al., 2013).

The milling of maize shows a reduction factor of about 4 for aflatoxins and about 10 for zearalenone from the grain to the final human products. Contrarily, concentration triplicates for both aflatoxins and zearalenone in the case of the by-products such as germs, bran, and animal flour.

Milling processes concentrate mycotoxins in animal-feed fractions

The milling and pre-milling processes reduce the content of mycotoxins in products for human consumption, but what about the parts removed and normally used in animal feeds? Several studies (Tibola et al., 2015; Hoffmans et al., 2022) indicate that the concentration of mycotoxins is higher in the wheat fractions intended for animal feeds such as bran, flour shorts screenings, and middlings. However, their level in feedstuffs is variable and affected by several factors such as the type of mycotoxins, the level and extent of fungal contamination, and the complexity of the cereal processing technology.

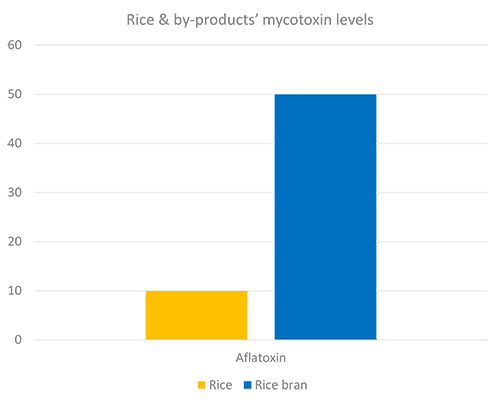

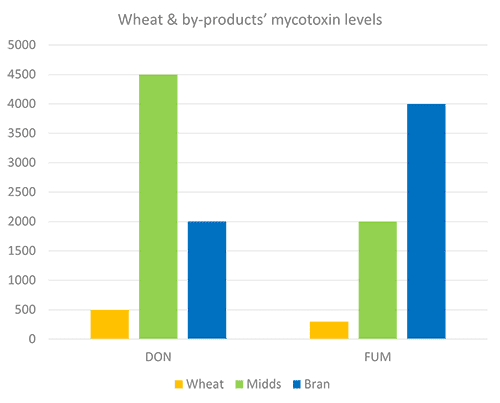

Compared to the concentration in wheat grain, these concentrations in by-products may be up to 800 % but more typically range from 150 % to 340 % (Cheli et al., 2013). EW Nutrition’s worldwide mycotoxin survey shows a similar trend (Figures 1 and 2), in which DON levels are nine times higher in wheat midds than wheat grains, and fumonisin is eight times higher in wheat bran.

Figure 1 + 2: Mycotoxins levels in grain and by-products

Highest concentrations in germ and bran fraction

After corn milling, animal feed fractions such as germ and bran have a low yield ranging from 5 to 7 % and are mostly composed of the outer parts of the kernels; as a consequence, an important concentration of mycotoxins occurs in these fractions (Schollenberger et al., 2008). When taking corn grains as the base, the contamination of aflatoxins goes up to three times in corn germ and up to nine times in bran (Brera et al., 2006; Pietri et al., 2009). For fumonisins, a double concentration can be expected (Brera et al., 2004), and for zearalenone, up to four times (Brera et al., 2006). Recently, Park and collaborators (2018) evaluated the distribution of 12 mycotoxins during wet milling of corn and found higher concentrations in corn gluten feed and corn bran.

Milling is a crucial step in the post-production of rice, in which the husk and the bran layers are removed. Rice bran is a common ingredient for animal feeds, in which aflatoxin is a common contaminant. It is believed that most of the aflatoxin contamination in rice bran occurs due to non-optimal storage conditions (Takahashi et al., 1989); however, a concentration of the toxin during milling of stored paddy rice also occurs, and the levels can triplicate compared with the grains (Trucksess et al., 2011).

The concentration of mycotoxins in DDGS during the ethanol production

Destillers’ dried grains with solubles (DDGS), a by-product of ethanol production, is a valuable feed ingredient, particularly as a source of protein for ruminants and monogastric animals at a competitive price.

Destillers’ dried grains with solubles (DDGS), a by-product of ethanol production, is a valuable feed ingredient, particularly as a source of protein for ruminants and monogastric animals at a competitive price.

Also here, mycotoxin contamination raises concerns with regard to their use in animal feeds. Mycotoxins are not destroyed during the ethanol fermentation process or during the production of DDGS. Moreover, a concentration of DON, ZEA, and fumonisin from corn to DDGS of 2–3.5 times has been reported for industrial ethanol production (Bennett et al., 1981; Schaafsma et al., 2009; Bowers & Munkvold, 2014).

In summary, studies on the fate of mycotoxins during food processing have shown that mycotoxins are concentrated in the fractions commonly used as animal feed. Moreover, high variability in mycotoxin contamination of cereal by-products has been evidenced, representing barriers to an increased acceptance of several food by-products as feed ingredients.

Feed formulation: Consider the mycotoxin contamination in by-products

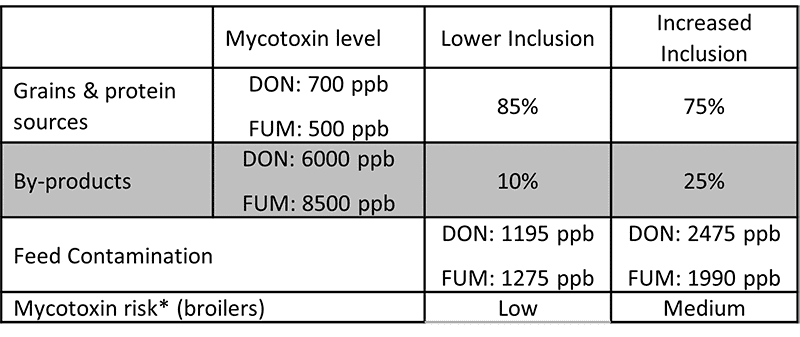

Higher inclusions of cereals have an impact on their safe use in feeds. To evaluate this impact, we can simulate two different scenarios with different inclusions of by-products:

Table 1: Different levels of by-products’ inclusion rates

Table 1: Different levels of by-products’ inclusion rates

*Risk Tool (masterrisktool.com)

In the first lower inclusion scenario, the risk for broilers in the starting phase considers the low inclusion of raw materials; the losses related to the contamination (without management) are mild. When increasing the levels of by-products, the risk category also increases. The losses are more important for the operation, ranging from gut barrier alterations with impaired production parameters to alterations in the immune response and increased susceptibility to disease.

Mycotoxins in by-products effective toxin risk management can help!

Given the pros of including cereal by-products in animal feeds, such as their saving potential and their link with sustainability of resources, their utilization is advisable; however, understanding how mycotoxin distribution and concentration change during grain processing is critical. Today’s knowledge is limited to a few mycotoxins in cereal milling.

Therefore, when considering using these by-products in the animal feed, we must bear in mind that:

- modified mycotoxins and mycotoxin co-contamination can be present, contributing to additive/synergistic effects on animal health.

- toxin risk management strategies, including analysis, risk evaluation, and risk mitigation must be pursued to prevent those undesired effects.

References:

Aureli, G., and M.G. D’Egidio. “Efficacy of Debranning on Lowering of Deoxynivalenol (DON) Level in Manufacturing Processes of Durum Wheat.” Tecnica Molit. 58 (2007): 729–33.

Bennett, G. A., A. A. Lagoda, O. L. Shotwell, and C. W. Hesseltine. “Utilization of Zearalenone- Contaminated Corn for Ethanol Production.” Journal of the American Oil Chemists’ Society 58, no. 11 (1981): 974–76. https://doi.org/10.1007/bf02659774.

Bowers, Erin, and Gary Munkvold. “Fumonisins in Conventional and Transgenic, Insect-Resistant Maize Intended for Fuel Ethanol Production: Implications for Fermentation Efficiency and DDGS Co-Product Quality.” Toxins 6, no. 9 (2014): 2804–25. https://doi.org/10.3390/toxins6092804.

Brera, Carlo, Carla Catano, Barbara de Santis, Francesca Debegnach, Marzia de Giacomo, Elena Pannunzi, and Marina Miraglia. “Effect of Industrial Processing on the Distribution of Aflatoxins and Zearalenone in Corn-Milling Fractions.” Journal of Agricultural and Food Chemistry 54, no. 14 (2006): 5014–19. https://doi.org/10.1021/jf060370s.

Brera,Carlo, Francesca, Debegnach, Silvana Grossi, and Marina Miraglia. “Effect of Industrial Processing on the Distribution of Fumonisin B1 in Dry Milling Corn Fractions.” Journal of Food Protection 67, no. 6 (2004): 1261–66. https://doi.org/10.4315/0362-028x-67.6.1261.

Cheli, Federica, Luciano Pinotti, Luciana Rossi, and Vittorio Dell’Orto. “Effect of Milling Procedures on Mycotoxin Distribution in Wheat Fractions: A Review.” LWT – Food Science and Technology 54, no. 2 (2013): 307–14. https://doi.org/10.1016/j.lwt.2013.05.040.

Park, Juhee, Dong-Ho Kim, Ji-Young Moon, Jin-Ah An, Young-Woo Kim, Soo-Hyun Chung, and Chan Lee. “Distribution Analysis of Twelve Mycotoxins in Corn and Corn-Derived Products by LC-MS/MS to Evaluate the Carry-over Ratio during Wet-Milling.” Toxins 10, no. 8 (2018): 319. https://doi.org/10.3390/toxins10080319.

Pascale, Michelangelo, Miriam Haidukowski, Veronica Maria Lattanzio, Marco Silvestri, Roberto Ranieri, and Angelo Visconti. “Distribution of T-2 and HT-2 Toxins in Milling Fractions of Durum Wheat.” Journal of Food Protection 74, no. 10 (2011): 1700–1707. https://doi.org/10.4315/0362-028x.jfp-11-149.

Pietri, A., M. Zanetti, and T. Bertuzzi. “Distribution of Aflatoxins and Fumonisins in Dry-Milled Maize Fractions.” Food Additives & Contaminants: Part A 26, no. 3 (2009): 372–80. https://doi.org/10.1080/02652030802441513.

Pinotti, Luciano, Matteo Ottoboni, Carlotta Giromini, Vittorio Dell’Orto, and Federica Cheli. “Mycotoxin Contamination in the EU Feed Supply Chain: A Focus on Cereal Byproducts.” Toxins 8, no. 2 (2016): 45. https://doi.org/10.3390/toxins8020045.

Ríos, G., L. Pinson-Gadais, J. Abecassis, N. Zakhia-Rozis, and V. Lullien-Pellerin. “Assessment of Dehulling Efficiency to Reduce Deoxynivalenol and Fusarium Level in Durum Wheat Grains.” Journal of Cereal Science 49, no. 3 (2009): 387–92. https://doi.org/10.1016/j.jcs.2009.01.003.

Schaafsma, Arthur W, Victor Limay-Rios, Diane E Paul, and J David Miller. “Mycotoxins in Fuel Ethanol Co-Products Derived from Maize: A Mass Balance for Deoxynivalenol.” Journal of the Science of Food and Agriculture 89, no. 9 (2009): 1574–80. https://doi.org/10.1002/jsfa.3626.

Schaarschmidt, Sara, and Carsten Fauhl-Hassek. “The Fate of Mycotoxins during the Processing of Wheat for Human Consumption.” Comprehensive Reviews in Food Science and Food Safety 17, no. 3 (2018): 556–93. https://doi.org/10.1111/1541-4337.12338.

Schollenberger, M., H.-M. Müller, M. Rüfle, S. Suchy, and W. Drochner. “Redistribution of 16FusariumToxins during Commercial Dry Milling of Maize.” Cereal Chemistry Journal 85, no. 4 (2008): 557–60. https://doi.org/10.1094/cchem-85-4-0557.

Takahashi, H., H. Yazaki, M. Manabe, S. Matsuura, and S. Kimura. “Distribution of Citrinin and Aflatoxins in Steamed Milled Rice Kernels Inoculated with Penicillium Citrinum and Aspergillus Flavus.” Mycotoxins 1990, no. 31 (1989): 49–53. https://doi.org/10.2520/myco1975.1990.49.

Trucksess, M.W., H.K. Abbas, C.M. Weaver, and W.T. Shier. “Distribution of Aflatoxins in Shelling and Milling Fractions of Naturally Contaminated Rice.” Food Additives & Contaminants: Part A 28, no. 8 (2011): 1076–82. https://doi.org/10.1080/19440049.2011.576441.