Global aquaculture has grown dramatically and shrimp cultivation areas, in particular, have expanded. Unfortunately, the shrimp industry, in particular, faces major problems with bacterial diseases. One of the most important diseases in shrimp is vibriosis. Mortality rates of up to 100 % are possible, so economic losses can be devastating.

Characteristics of vibriosis

Vibriosis generally occurs in all life stages, but mainly in hatcheries. Vibrios are found as normal flora in the hepatopancreas of the healthy crustacean. They can turn from tolerated to pathogenic, if environmental conditions are compromised: e.g. over / underfeeding, overcrowding or decreased levels of oxygen.

The animals can be infected orally, through wounds in the exoskeleton or pores, the gills or the midgut. There are different expressions of the disease depending on which parts of the animal are affected (e.g. appendage and cuticular vibriosis).

Negative effects on the ecology

As antibiotics for shrimps are applied orally together with the feed, not all of them reach their target. An estimated 15-40 % are not ingested due to feeding falling to the bottom. A fraction of the ingested antibiotics is also not absorbed in the body and is excreted. All of these antibiotics stay in the water or sink to the bottom. The number of antibiotics that remain in the water or sediment varies from 1 % (chloramphenicol) up to 90 % (Oxytetracycline).

It is estimated that 70-90 % of antibiotics used in the therapy of farmed organisms end up in the environment and sediment and lead to the development of antibiotic resistance.

Secondary Plant Compounds (SPCs) – a good tool to reduce the use of antibiotics?

SPCs and their components are able to slow down or prevent the growth of molds, viruses, and bacteria. They impair them by acting at different parts/mechanisms of the cells (e.g. cell membrane, transport systems, cell contents, flagella development, quorum sensing…). The best-explained mode of action is one of thymol and carvacrol extracted from thyme and oregano. These substances are able to penetrate the bacterial membrane and disrupt its integrity causing loss of ions or energy equivalents.

Several trials conducted show the high efficacy of secondary plant compounds in aquaculture.

1. Scientific Trial (Kasetsart University, Thailand)

Design

a) 4 groups (6 replicates each) of White Leg Shrimp (L. vannamei) were housed in 100 L aquaria with 10 animals each.

Control: Standard feed, no additive

AB-Group: Standard feed + 10 ppm Enrofloxacin

Activo® Group 1: Standard feed + 100 g Activo®/t of feed

Activo® Group 2: Standard feed + 200 g Activo®/t of feed

Evaluation of mortality and specific growth

a) End of the feeding trial: stressing of the shrimp (high water temperature, 33°C for 1 hour), then challenge with Vibrio parahaemolyticus (7,6 x 106 cfu/ml) by subcutaneous injection.

Evaluation of mortality

a) Survival rates in the AB-Group (93,3 %) and in the Activo® Group 2 (90,0 %) were similar. The specific growth rate of the AB-Group (2,32 %/day) and the Activo® Group 2 (2,22 %/day) were higher than the control (1,94 %/day). The Activo® Group 1 (2,18 %/day) ranged performance-wise between the control and AB-Group.

b) After the challenge, mortality in the control group (43,3%) was approximately twice as high as in the AB-Group (20 %) and in the two Activo® groups (both 23,3%).

2. Field Trial (Shrimp farm Ecuador)

Design

Two ponds with 80.000 shrimps/ha

Control (3 ha): standard feed

Activo® Aqua Group (5 ha): standard feed + 2 kg Activo® Aqua (Activo® upgraded by immune system stimulating- mannan-oligosaccharides) /t of feed on top

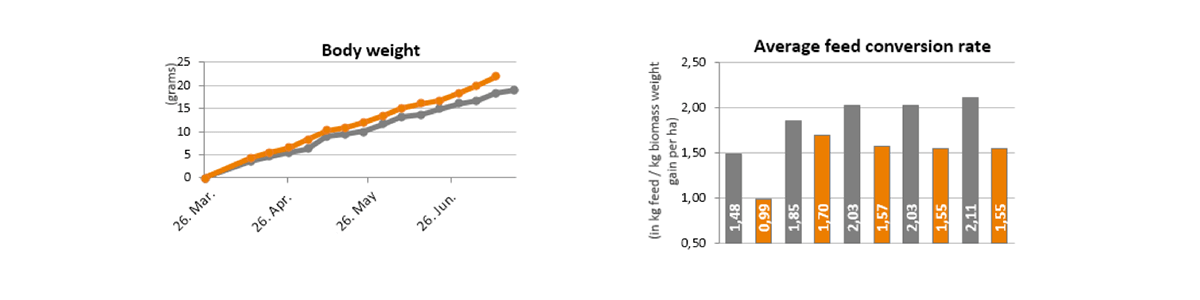

Evaluation of average shrimp weight at regular intervals

Results

Activo® Aqua Group showed a consistently better development of body weight compared to the control, resulting in a shorter cultivation period until harvesting (112 compared to 123) and therefore a higher turnover of animals. Feed conversion in the Activo® Aqua group was better in every growth stage.

Both trials present secondary plant compounds as a good alternative to antibiotic growth promoters. In the case of disease, they decrease mortality. Under standard conditions, the improved development shortens time to harvest and increases the turnover. The improved feed conversion lowers feeding costs.