By Predrag Persak, Regional Technical Manager, EW Nutrition

In light of sustainability requirements, shortage of feed materials, and constant pressure on energy efficiency, we must rethink how we deal with all elements that impact our production. Shrinkage is one of the essential impacting elements.

What is Shrinkage?

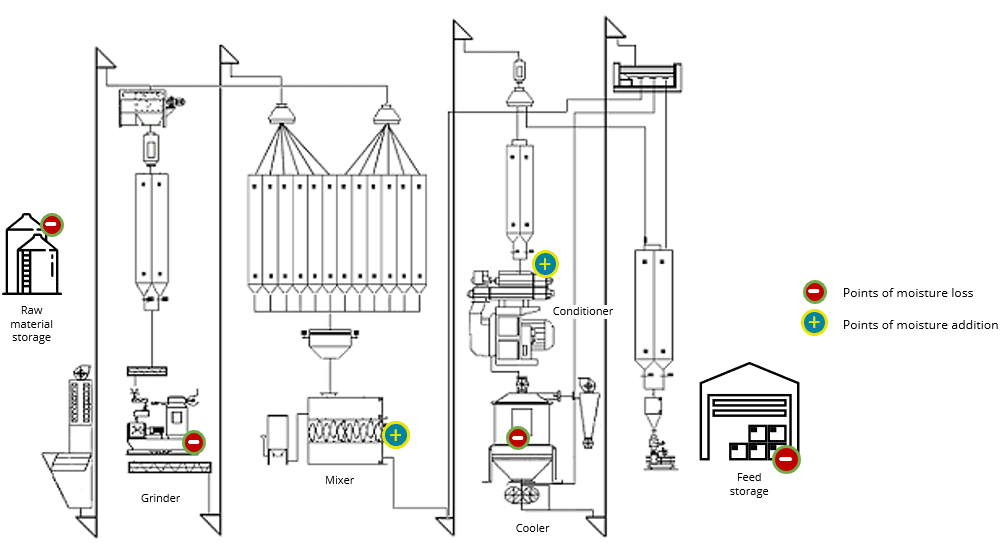

In simple terms, shrinkage is the weight loss in feed or feed materials during receiving, processing, or storage. Shrinkage happens on the farm level but also in feed mills. In this article, we will focus on the latter one. Points or reasons why this happens are diverse but not unknown. Wastages, dust, pests, moisture loss, and scale deviations are some of the most important. Through time, we found efficient ways to close the doors to feather and fur pests that were stealing valuable resources and causing shrinkage. We are also good at weight control when receiving and dispatching, by thoroughly balancing the scales. But one point related to the core of feed production – and the most significant loss – is still left untackled. That is moisture loss through grinding.

Figure 1: Points of moisture loss and addition in the feed mill

Grinding is one central point of shrinkage

Grinding and subsequent particle size reduction is essential from many points (handling, nutritional, processing, mixing uniformity, …) and is unavoidable if we want to produce excellent feed. In the case of grinding with hammer mills, we use kinetic energy to make the hammers beat kernels to the desired size. This is a very efficient process. However, during that process, a part of kinetic energy is also transferred to thermal, increasing the temperature of the processed feed materials and resulting in the loss of one part of valuable moisture. Also, due to size reduction and enlargement of the surface, there is much more place for evaporation and moisture movement. Losses can be up to 2%. One essential parameter for high pellet quality is the particle size, but very fine grinding will result in higher shrinkage through moisture and dust losses.

Moisture is decisive ̶ we must manage it!

The valuable moisture is needed for many reasons. One is weight. Another reason is that nutritional density for feed materials is calculated considering a certain moisture content. Additionally, moisture influences the processing parameters during the pelleting process (targeted moisture content in the conditioner should be 16-18%). Since moisture loss is unavoidable and represents the most significant part of loss or shrinkage, we must manage it. For this purpose, we must substitute lost moisture with added moisture. And in that process, we have a short time to do it properly. Usually, we don´t have enough time for so-called “soaking”. However, with the help of surfactants, the process can be speeded up.

Surf-Ace helps to keep the moisture in the feed

Surf-Ace, a liquid preservative premix for moisture optimization, which contains organic acids / organic acid salts, emulsifiers, and surfactants, helps to keep the moisture in the feed. Conditioning can be hindered by surface tension because water forms a film on the surface of the feed particles, or oil covers the particles. Surf-Ace improves water penetration and retention by decreasing surface tension. Trials show the moisture-optimizing effect of Surf-Ace.

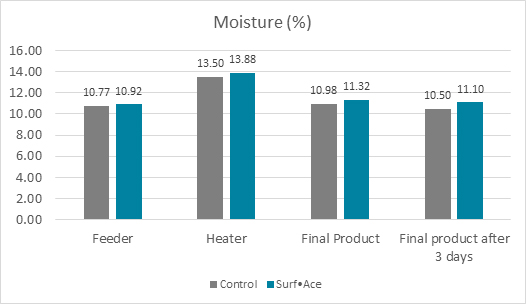

A trial conducted in Jordan demonstrated an increase in moisture in different processing phases (feeder, heater, and the final product). It also showed better maintenance of water in the product during storage (Fig. 2).

Figure 2: Surf-Ace achieved higher moisture levels in different phases of the feed production process

Figure 2: Surf-Ace achieved higher moisture levels in different phases of the feed production process

Two further trials conducted in Poland and Serbia also showed that feed millers could increase moisture in the final feed by using Surf-Ace (Fig. 3).

Figure 3: Surf-Ace provided for higher moisture content in the feed

Figure 3: Surf-Ace provided for higher moisture content in the feed

Effective surfactants minimize shrinkage in feed

Shrinkage in times of increasing costs must be minimized by all means. The feed industry offers surfactants that keep the moisture in the feed during processing and prevent at least this part of shrinkage.

Besides the financial aspect, the optimal moisture content in feed and feed materials is important to provide high feed quality, whether concerning pellet quality or percentage of nutrients. Using surfactants, therefore, not only increases profitability but also does its bit concerning sustainability.