By T.J. Gaydos

Coccidiosis control consists of programs, including ionophores, chemical coccidiostats, vaccines, and gut health-promoting natural products. Sometimes, these are combined (Noack, Chapman, and Selzer, 2019). Antibiotic-free (ABF) production requires new approaches – this article will look at how different solutions can be successfully implemented.

Meticulous coccidiosis management in ABF productions is crucial to safeguard animal welfare and performance.

Meticulous coccidiosis management in ABF productions is crucial to safeguard animal welfare and performance.

What makes up a successful coccidiosis control program for ABF systems?

When managing a poultry program without antibiotics in the U.S., where ionophores are classified as antibiotics, the only available tools for coccidiosis control are vaccines, chemical coccidiostats, and natural products supporting gut health during challenging times.

- The use of a chemical-only program is possible and often successful. Still, the choice of chemicals is limited, and the risk of building resistance must always be considered and managed through the appropriate rotation of active ingredients.

- A second option is a coccidiosis vaccine with or without chemical coccidiostats. This is an excellent long-term option but the most difficult to manage.

- A third effective option is a coccidiosis vaccine combined with the use of phytomolecule-based solutions contributing to the coccidiosis control program and delivering improved gut health.

What do most ABF newcomers do?

When making the transition from conventional to ABF production, broiler producers usually try:

- A chemical coccidiostat program,

- A bio-shuttle program: a coccidiosis vaccine, followed by a chemical coccidiostat, or

- Phytomolecule-based feed additives; typically, in combination with a coccidiosis vaccine or chemical program.

When the operation can master managing the coccidiosis vaccine and other husbandry challenges, the optimal solution is the combination of vaccination and phytomolecule-based feed supplements.

Why a combination?

A coccidiosis control program based on vaccination begins in the hatchery and continues through live production. Its success relies on many moving parts working in sync to produce the desired result of early uniform immunity to coccidiosis. Phytomolecule-based products additionally can support the animals in terms of gut health, oxidative balance, and immunity.

Vaccination success depends on attention to detail

If one decides to use vaccination for coccidiosis control, the following points must be considered to achieve high effectiveness.

Vaccine storage – the right temperature is crucial

Proper storage is essential for all vaccines. In general, coccidiosis vaccines should be stored between 2° to 7°C (35° to 45°F), but optimally, one asks the vaccine manufacturer for product-specific directions. Coccidiosis vaccines must not freeze. Freezing will severely damage or kill the oocysts, thus significantly reducing efficacy. It is also important to ensure that there are no cold spots in the refrigerator. Hence, vaccines should be stored in the middle of a shelf with air space around or in a foam-insulated place inside the fridge.

For monitoring the temperature, an analog high/low thermometer should be placed by the vaccine. The temperature should be recorded, and the thermometer reset daily. To minimize the risk of administering a frozen vaccine, it is recommended to put freeze indicators outside the boxes. If, despite all these measures, vaccines are suspected to have frozen, segregate the suspect product and contact the supplier for assistance.

Vaccine administration – mind an even distribution for all steps

The goal of vaccination is to build early and uniform immunity in all chickens, which is achieved by exposure to repeated cycles of coccidia replication in the intestine.

1. Even distribution of the oocysts in the vaccine

It is essential to ensure that all oocysts flow from the bottle into the distribution jug when mixing the vaccine. The oocysts should be well-mixed and then must be constantly agitated to remain suspended in solution. The most common way to suspend oocysts is to use a small air pump to bubble the vaccine, creating turbulence.

2. Even spraying of the vaccine onto the chicks

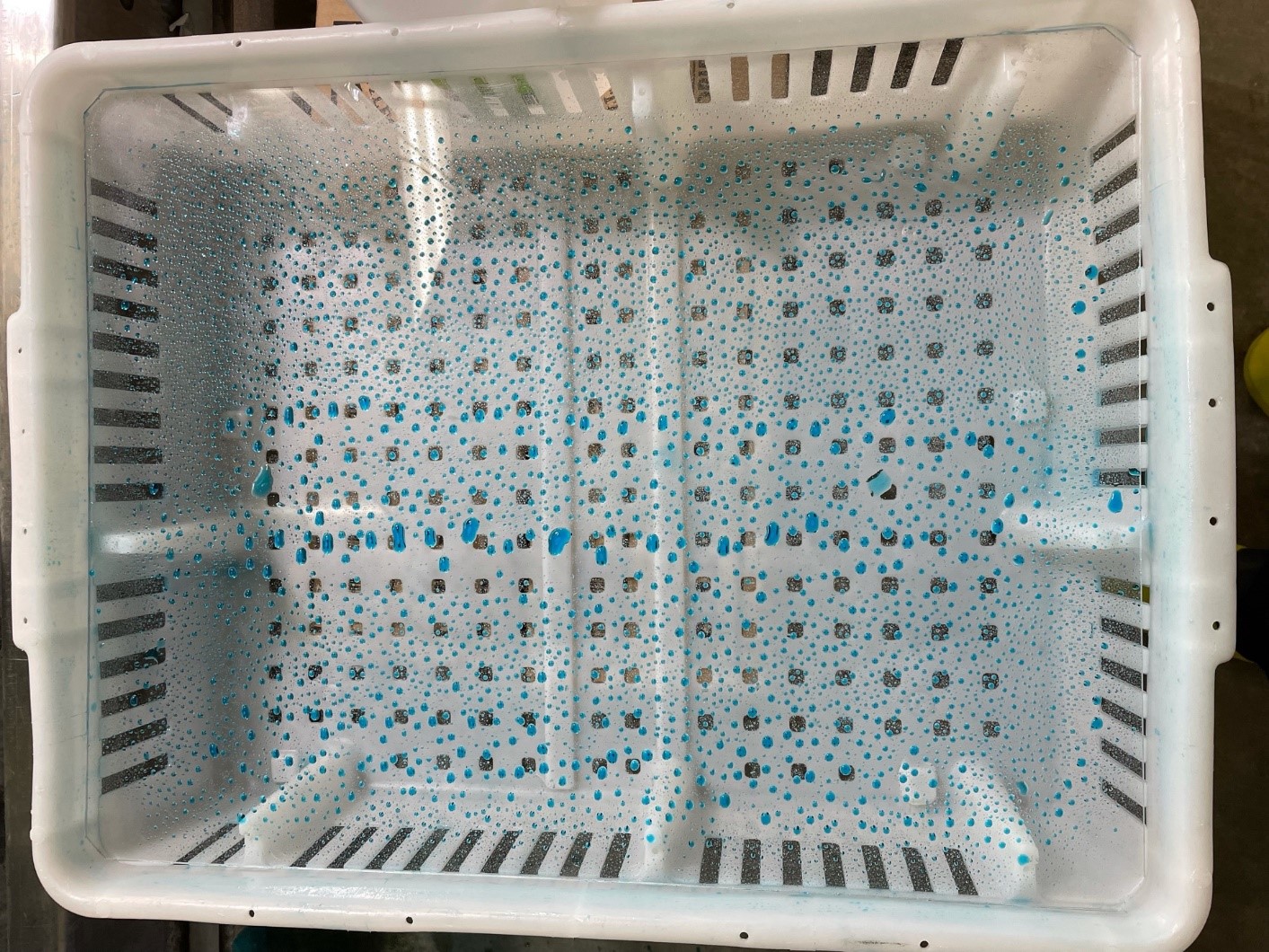

The next important step is to ensure that the chicks are evenly covered with the vaccine. When in doubt, run a chick box through the spray cabinet, collect the nozzles’ output, and measure the volume sprayed. To check the spray pattern, set a piece of clear hard plastic on top of the pegs in the chick basket and run the box through the spray cabinet. Evaluate the spray pattern on the plastic sheet and adjust as needed to ensure an even spraying. The spray pattern should be checked every time a new batch of vaccines is mixed.

Even spraying of coccidiosis vaccine can be easily tested using a clear plastic sheet.

Even spraying of coccidiosis vaccine can be easily tested using a clear plastic sheet.

3. A similar amount of vaccine intake for all chicks

Coccidiosis vaccines must be preened and consumed to be effective. Adding a dye to the spray compatible with the vaccine will help stimulate the birds to preen. A well-lit and temperature-controlled processing and holding area will promote preening behavior. Tongues should be checked regularly to ensure that chicks consume the vaccine. At a minimum, check ten birds per basket and ten baskets per lot. More than 98% of birds should have evidence of vaccine consumption within 10-15 minutes post-vaccination.

Chick vitality is a critical success factor in an ABF program. Healthy chicks perform better in the field. In the context of a coccidiosis vaccine, they are more apt to preen, more likely to consume food and water quickly, and less likely to excessively pick at the litter.

A dye helps to evaluate if the coccidiosis vaccine was evenly sprayed across all chicks.

Uniform immunity through effective farm management

A successful coccidiosis vaccination program achieves uniform immunity against coccidia, which slowly develops from the hatchery. For this purpose, birds must be evenly spread throughout all stages of growth to seed the litter evenly with oocysts and to have even coccidiosis pressure in all parts of the house.

Time management allows even immunization

Birds should be turned out from half to full house between 9 and 11 days. This schedule allows the birds to excrete the first round of oocysts and for the oocysts to sporulate and be consumed by the birds.

The birds need to be moved to full house before they secrete the second round of oocysts. This will allow the oocysts to be spread uniformly in the house. Coccidia reproduce exponentially and the second round of oocyst production is significantly more numerous than the first.

It is possible to brood birds in the full house while on coccidiosis vaccine. Still, it is complicated to manage the coccidiosis cycling because bird density is generally too low to ensure that birds effectively cycle the vaccine strain oocysts.

Litter consistency is decisive

Litter management is essential to control the cycling of coccidiosis because one stage of the life cycle of coccidia occurs in the litter. Litter moisture of 25% is ideal. When litter is squeezed in a fist, it should briefly form and immediately break apart. If it stays formed, it is too wet. If the litter is free-flowing and dusty, it is too dry for adequate sporulation.

Non-antibiotic supplements support coccidiosis management

Managing coccidiosis cycling requires attention to detail and is probably the most challenging part of adequately managing an ABF program. All farms are not equal and need to be supervised according to their specific needs. The use of non-antibiotic feed and water additives can help control coccidiosis and other enteric diseases.

Some non-antibiotic supplements have anticoccidial (e.g. amprolium, saponins, tannins) or antibacterial (e.g., plant extracts) activity. When used correctly, these may improve the performance of birds in a vaccination or chemical-based coccidiosis control program. Other non-antibiotic alternatives such as probiotics, prebiotics, organic acids, and yeast cell wall extracts have been shown to improve gastrointestinal health. The combination of excellent animal husbandry and the correct feed/water additive program is the key to success.

References

Noack, Sandra, H. David Chapman, and Paul M. Selzer. “Anticoccidial Drugs of the Livestock Industry.” Parasitology Research 118, no. 7 (2019): 2009–26. https://doi.org/10.1007/s00436-019-06343-5.