Masked mycotoxins – particularly dangerous for dairy cows

By Si-Trung Tran, SEAP Regional Technical Manager, EW Nutrition

Technical Team and Dr. Inge Heinzl, Editor, EW Nutrition

Mycotoxins are secondary metabolites of fungi, commonly found as contaminants in agricultural products. In some cases, these compounds are used in medicine or industry, such as penicillin and patulin. In most cases, however, they are considered xenobiotics that are toxic to animals and humans, causing the disease collectively known as mycotoxicosis. The adverse effects of mycotoxins on human and animal health have been documented in many publications. Aflatoxins (AFs) and deoxynivalenol (DON, vomitoxin) are amongst the most critical mycotoxins affecting milk production and -quality.

Aflatoxins do not only affect cows

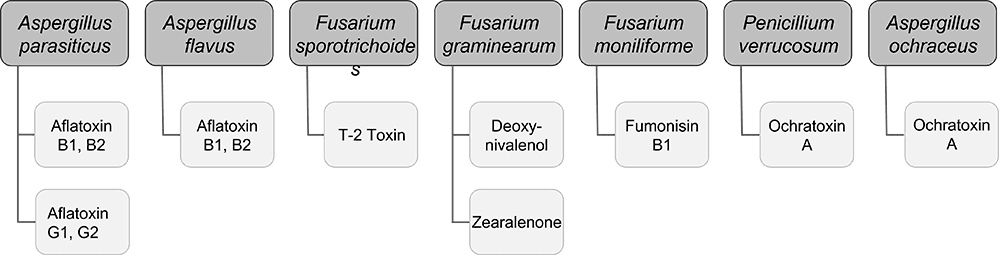

Aflatoxins (AFs) are highly oxygenated, heterocyclic difuranocoumarin compounds produced by Aspergillus flavus and Aspergillus parasiticus. They colonize crops, including many staple foods and feed ingredients. Within a group of over 20 AFs and derivatives, aflatoxin B1 (AFB1), B2, G1, and G2 are the most important naturally occurring compounds.

Among the aflatoxins, AFB1 is the most widespread and most toxic to humans and animals. Concern about mycotoxin contamination in dairy products began in the 1960s with the first reported cases of contamination by aflatoxin M1 (AFM1), a metabolite of AFB1 formed in the liver of animals and excreted in the milk.

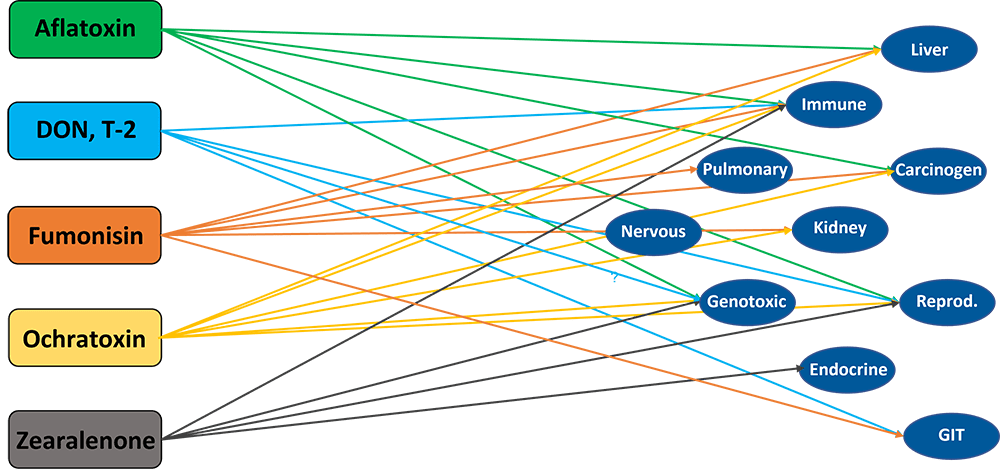

There is ample evidence that lactating cows exhibit a significant reduction in feed efficiency and milk yield within a few days of consuming aflatoxin-contaminated feed. At the cellular level, aflatoxins cause degranulation of endoplasmic membranes, loss of ribosomes from the endoplasmic reticulum, loss of nuclear chromatin material, and altered nuclear shapes. The liver, as the organ mainly dealing with the decontamination of the organism, gets damaged, and performance drops. Immune cells are also affected, reducing immune competence and vaccination success (Arnold and Gaskill, 2023).

DON reduces cows’ performance

Another mycotoxin that can also reduce milk quality and affect metabolic parameters, as well as the immune function of dairy cows, is DON. DON is produced by different fungi of the Fusarium genus that infect plants. DON synthesis is associated with rainy weather from crop flowering to harvest. Whitlow and co-workers (1994) reported the association between DON and poor performance in dairy herds and showed decreased milk production in dairy cows fed 2.5 mg DON/kg. However, in cows fed 6 to 12 mg DON/kg dry matter for 10 weeks, no DON or its metabolite DOM-1 residues were detected in milk.

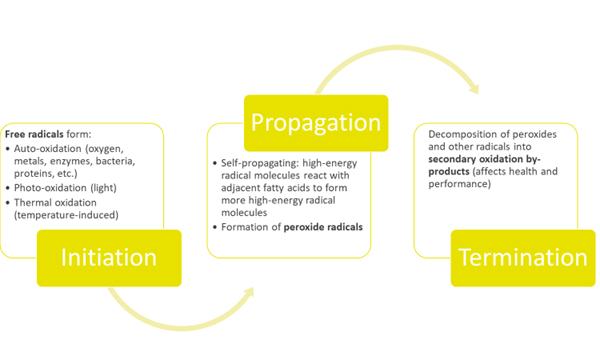

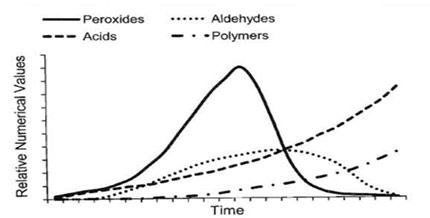

Masked mycotoxins hide themselves during analysis

Plants suffering from fungal infestations and thus confronted with mycotoxins convert the harmful forms of mycotoxins into less harmful or harmless ones for themselves by conjugation to sulfates, organic acids, or sugars. Conjugated mycotoxins cannot always be detected by standard analytical methods. However, in animals, these forms can be released and transformed into parent compounds by enzymes and microorganisms in the gastrointestinal tract. Thus, the feed may show a concentration of mycotoxins that is still below the limit value, but in the animal, this concentration is suddenly much higher. In dairy cows, the release of free mycotoxins from conjugates during digestion may play an important role in understanding the silent effects of mycotoxins.

Fusarium toxins, in particular, frequently occur in this “masked form”. They represent a serious health risk for animals and humans.

Aflatoxins first show up in the milk

Masked aflatoxins may also play a role in total aflatoxin contamination of feed materials. Research has harvested little information on masked aflatoxins that may be present in TMR ingredients. So far, metabolites such as Aflatoxin M2 have been identified (Righetti, 2021), which may reappear later in milk as AFM1.

DON-related symptoms without DON?

Sometimes, animals show DON-related symptoms, with low levels detected in the feed or raw materials. Besides sampling errors, this enigma could be due to conjugated or masked DON, which is structurally altered DON bound to various compounds such as glucose, fatty acids, and amino acids. These compounds escape conventional feed analysis techniques because of their modified chemical properties but can be released as their toxic precursors after acid hydrolysis.

Masked DON was first described in 1984 by Young and co-workers, who found that the DON content of yeast-fermented foods was higher than that of the contaminated wheat flour used in their production. The most plausible reason for this apparent increase was that the toxin from the wheat had been converted to a compound other than DON, which could be converted back to DON under certain conditions. Since this report, there has been much interest in conjugated or masked DON.

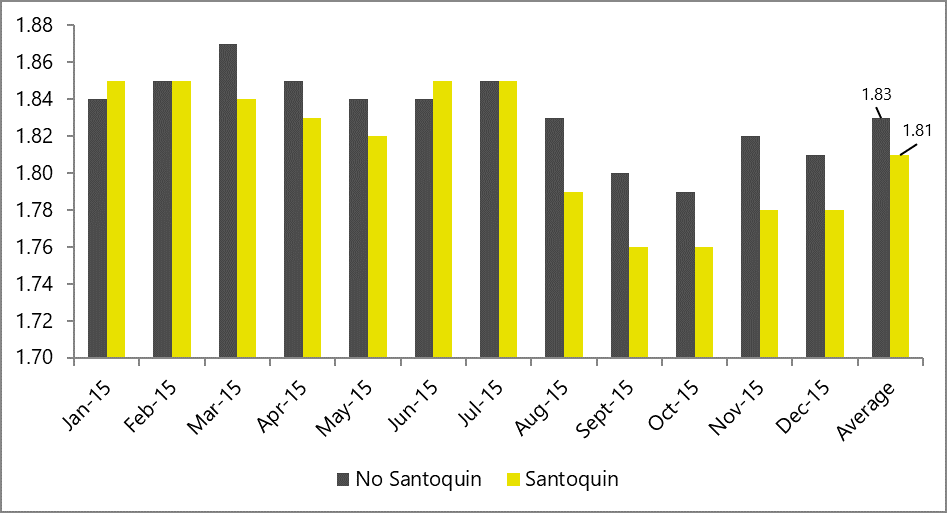

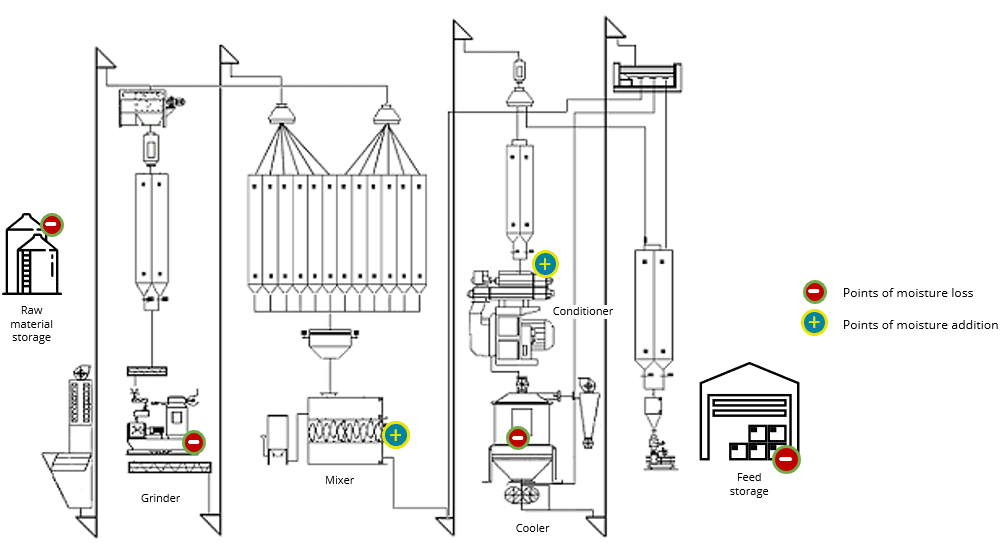

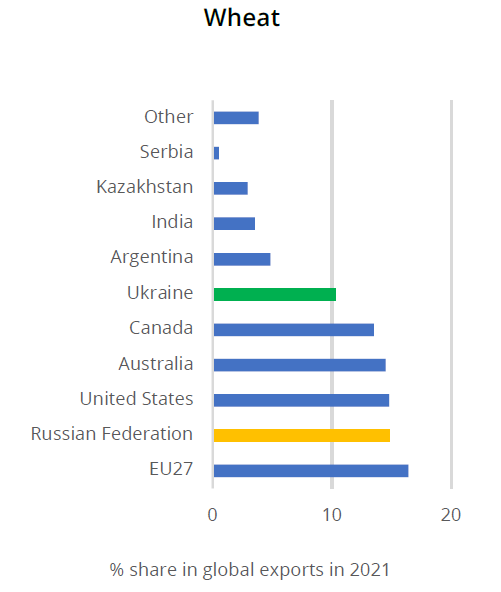

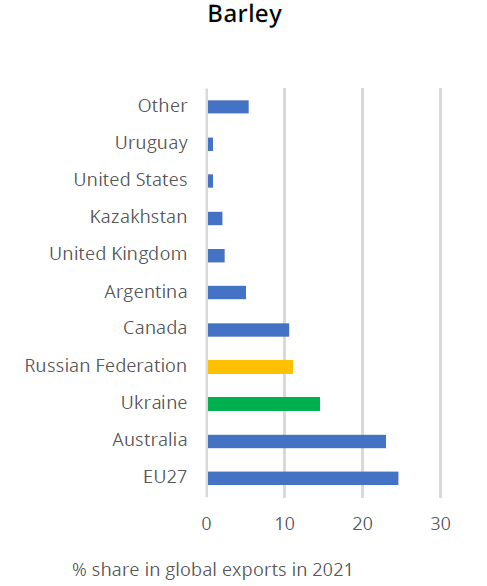

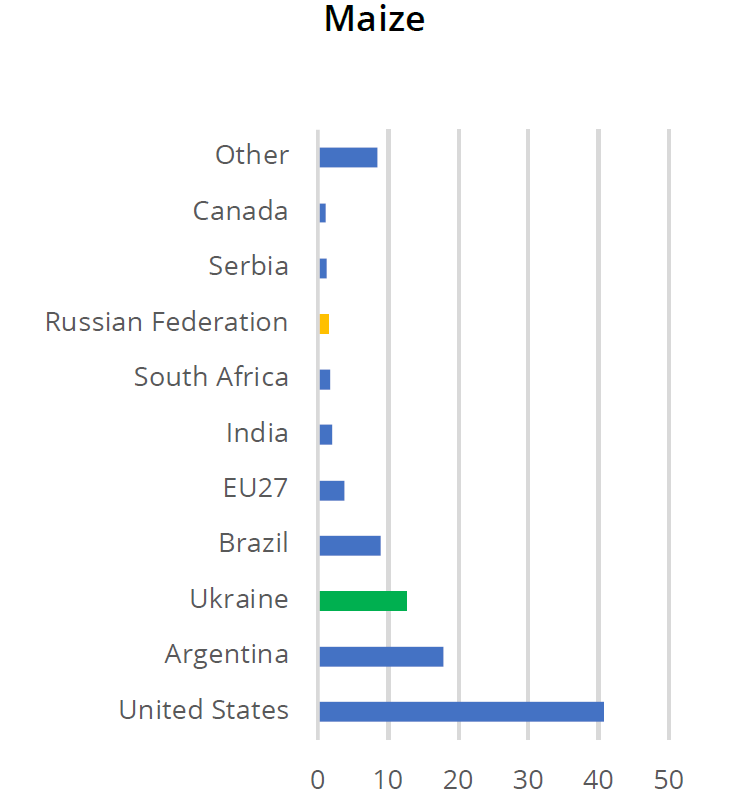

Silage: masked DON is a challenge for dairy producers

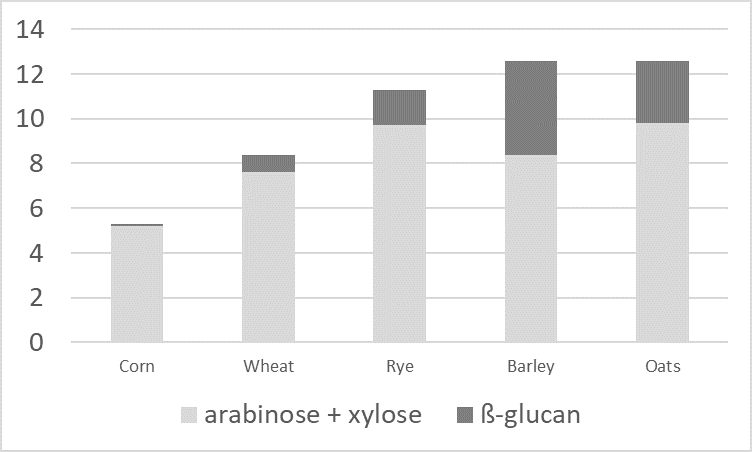

Silage is an essential feed for dairy cows, supporting milk production. Most silage is made from corn and other grains. The whole green plant is used, which can be infected by fungi. Since infection of corn with Fusarium spp. and subsequent DON contamination is usually a major problem in the field worldwide, a relatively high occurrence of this toxin in silage must be expected. The ensiling process may reduce the amount of Fusarium fungi, but the DON formed before ensiling is very stable.

Silage samples show DON levels of concern

It is reasonable to assume that the DON biosynthesized by the fungi was metabolized by the plants to a new compound and thus masked DON. Under ensiling conditions, masked DON can be hydrolyzed, producing free DON again. Therefore, the level of free DON in the silage may not reflect the concentration measured in the plants before ensiling.

A study analyzed 50 silage samples from different farms in Ontario, Canada. Free DON was found in all samples, with levels ranging from 0.38 to 1.72 µg/g silage (unpublished data). Eighty-six percent of the samples contained DON at concentrations higher than 0.5 µg/g. Together with masked DON, it poses a potential threat to dairy cattle.

Specific hydrolysis conditions allow detection

However, in the natural ensiling process, the conditions for hydrolysis of masked DON are not optimal. The conditions that allow improved analysis of masked DON were recently described. This method detected masked DON in 32 of 50 silage samples (64%) along with free DON, increasing DON concentration by 23% in some cases (unpublished data).

Mycotoxins impact humans and animals

Aflatoxins, as well as DON, have adverse effects. In the case of DON, the impact on the animal is significant; in the case of aflatoxin, the possible long-term effects on humans are of higher relevance.

DON has more adverse effects on the animal and its performance

Unlike AFs, DON may be found in milk at low or trace concentrations. It is more associated with negative effects in the animal, altered rumen fermentation, and reduced flow of usable protein into the duodenum. For example, milk fat content was significantly reduced when cows were fed 6 µg DON/kg. However, the presence of DON also indicates that the feed probably contains other mycotoxins, such as zearalenone (ZEA) (estrogenic mycotoxin) and fusaric acid (pharmacologically active compound). All these mycotoxins may interact to cause symptoms that are different or more severe than expected, considering their individual effects. DON and related compounds also have immunosuppressive effects, resulting in increased somatic cell counts in milk. The U.S. FDA has established an action level for DON in wheat and wheat-derived products intended for cows, which is 5µg DON/g feed and the contaminated ingredient must not exceed 40% of the ration.

Aflatoxins decrease milk quality and pose a risk to humans

Aflatoxins are poorly degraded in the rumen, with aflatoxicol being the main metabolite that can be reconverted to AFB1. Most AFs are absorbed and extensively metabolized/hydrolyzed by enzymes found mainly in the liver. This results in the formation of AFM1, a part of which is conjugated to glucuronic acid and subsequently excreted in the bile. The other part enters the systemic circulation. It is either excreted in urine or milk. AFM1 appears within 12-48 hours after ingestion in cow’s milk. The excreted amount of AFM1 in milk from dairy cows usually ranges from 0.17% to 3% of the ingested AFB1. However, this carryover rate may vary from day to day and from one milking to the next in individual animals, as it is influenced by various factors, such as feeding regime, health status, individual biotransformation capacity, and, of course, by actual milk production. Carryover rates of up to 6.2% have been reported in high-yielding dairy cows producing up to 40 liters of milk per day.

In various experiments, AFM1 showed both carcinogenic and immunosuppressive effects. Accordingly, the International Agency for Research on Cancer (IARC) classified AFM1 as being in Group 2B and, thus, possibly carcinogenic in humans. The action level of 0.50 ppb and 0.05 ppb for AFM1 in milk is strictly adhered to by the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), respectively.

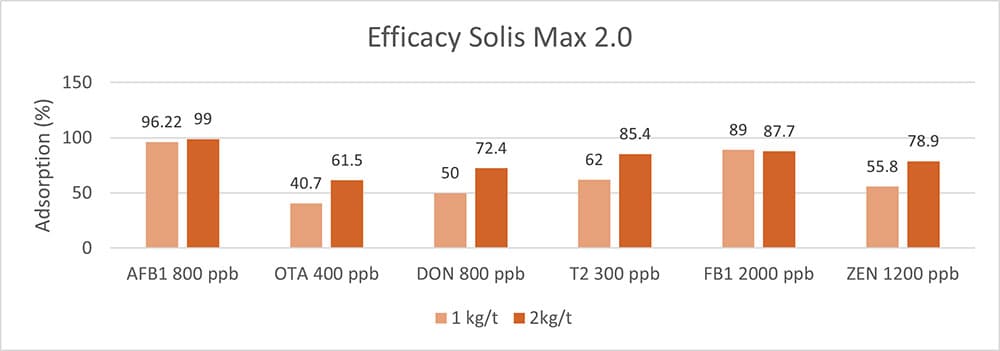

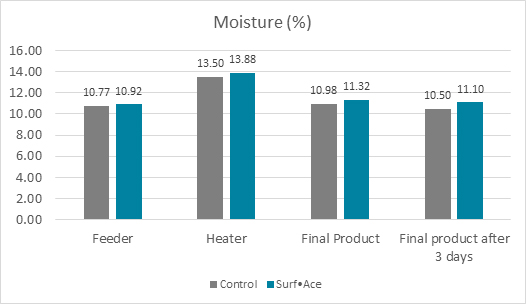

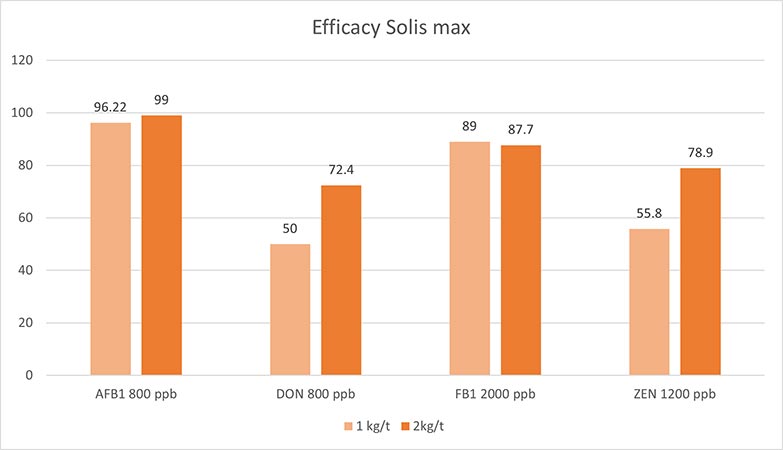

Trials show the high adsorption capacity of Solis Max

A trial was conducted at an independent laboratory located in Spain. The evaluation of the performance of Solis Max was executed with the following inclusion levels:

- 0.10% equivalent to 1.0 kg of Solis Max per ton of feed

- 0.20% equivalent to 2.0 kg of Solis Max per ton of feed

A phosphate buffer solution at pH 7 was prepared for the trial to simulate rumen conditions. Each mycotoxin was tested separately, preparing solutions with known contamination (final concentration described in the table below). The contaminated solutions were divided into 3 parts: A positive control, 0.10% Solis Max and 0.20% Solis Max. All samples were incubated at 41°C for 1 hour, centrifuged, and the supernatant was analyzed for the mycotoxin added to determine the binding efficacy. All analyses were carried out by high-performance liquid chromatography (HPLC) with standard detectors.

| Mycotoxin | Contamination Level (ppb) |

| Aflatoxin B1 | 800 |

| DON | 800 |

| Fumonisin B1 | 2000 |

| ZEA | 1200 |

Results:

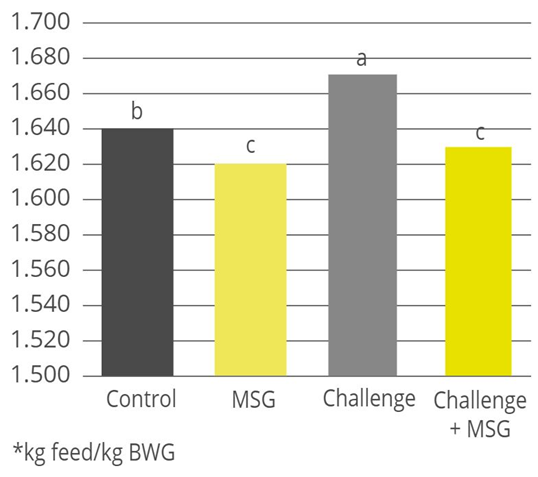

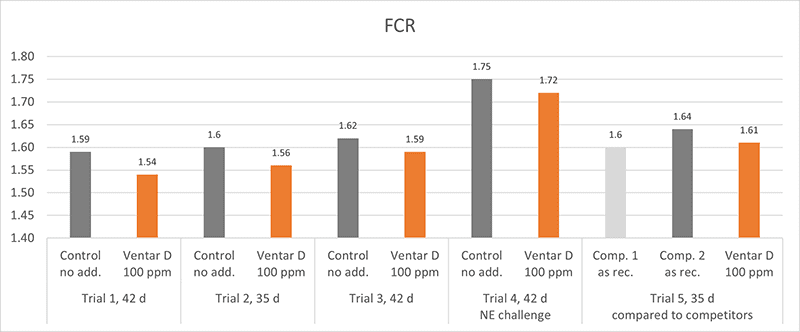

The higher concentration of Solis max showed a higher adsorption rate for most mycotoxins. The high dose of Solis Max adsorbed 99% of the AFB1 contamination. In the case of DON, more than 70% was bound. For fumonisin B1 and zearalenone, Solis max showed excellent binding rates of 87.7% and 78.9%, respectively (Figure 1).

Figure 1: Solis Max showed a high binding capacity for the most relevant mycotoxins

Figure 1: Solis Max showed a high binding capacity for the most relevant mycotoxins

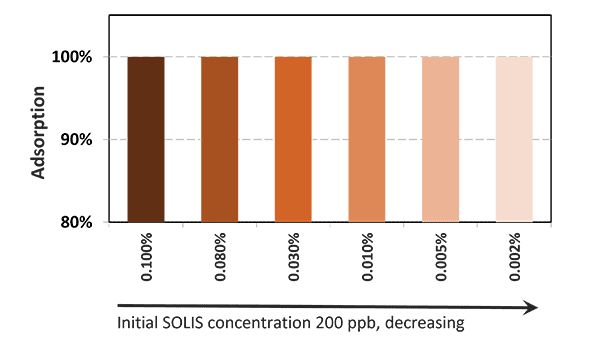

Another trial was conducted at an independent laboratory serving the food and feed industry and located in Valladolid, Spain.

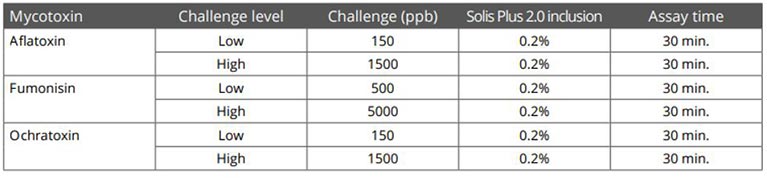

All tests were carried out as duplicates and using a standard liquid chromatography/mass spectrometry (LC/MS/MS) quantification. Interpretation and data analysis were carried out with the corresponding software. The used pH was 3.0, toxin concentrations and anti-mycotoxin agent application rates were set as follows (Table 1):

Table 1: Trial set-up testing the binding capacity of Solis Plus 2.0 for several mycotoxins in different contamination levels

Table 1: Trial set-up testing the binding capacity of Solis Plus 2.0 for several mycotoxins in different contamination levels

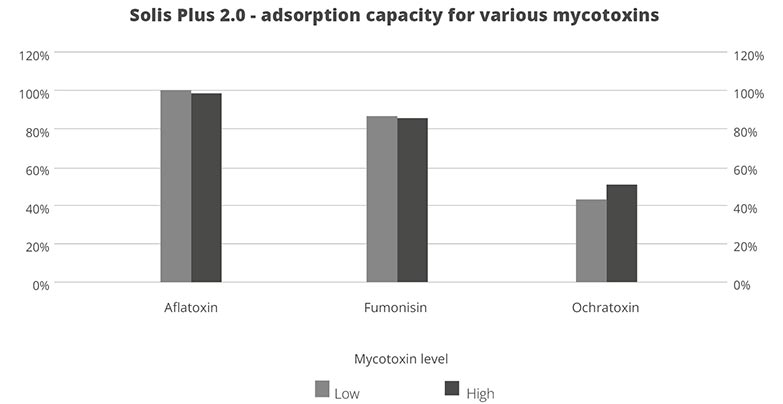

Results:

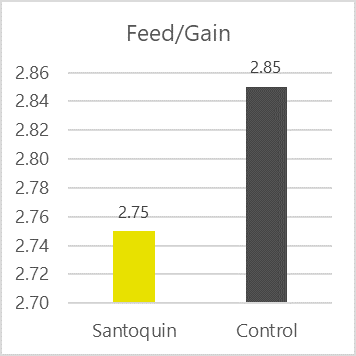

Under acidic conditions (pH3), Solis Plus 2.0 effectively adsorbs the three tested mycotoxins at low and high levels. 100% binding of aflatoxin was achieved at a level of 150ppb and 98% at 1500ppb.In the case of fumonisin, 87% adsorption could be reached at 500ppb and 86 for a challenge with 5000ppb. 43% ochratoxin was adsorbed at the contamination level of 150ppb and 52% at 1500ppb.

Figure 2: The adsorption capacity of Solis Plus 2.0 for three different mycotoxins at two challenge levels

Figure 2: The adsorption capacity of Solis Plus 2.0 for three different mycotoxins at two challenge levels

Mycotoxins – Effective risk management is of paramount importance

Although the rumen microflora may be responsible for conferring some mycotoxin resistance to ruminants compared to monogastric animals, there are still effects of mycotoxins on rumen fermentation and milk quality. In addition, masked mycotoxins in feed present an additional challenge for dairy farms because they are not readily detectable by standard analyses.

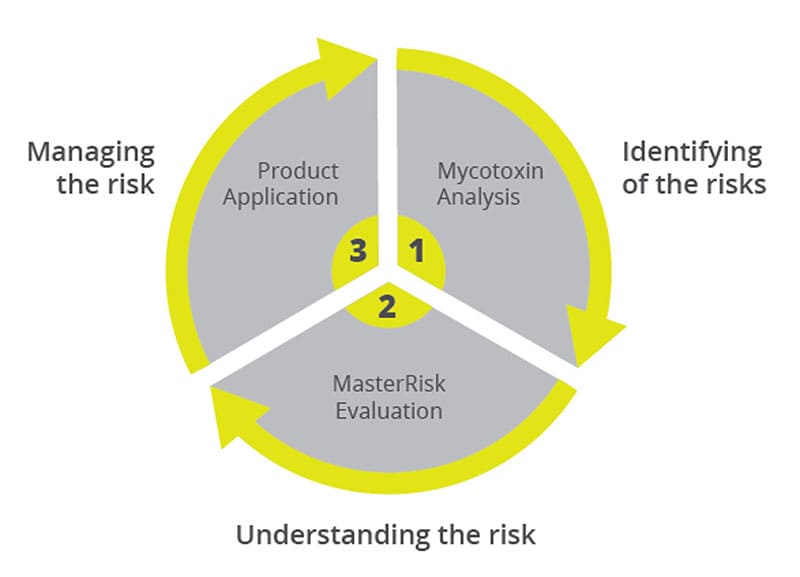

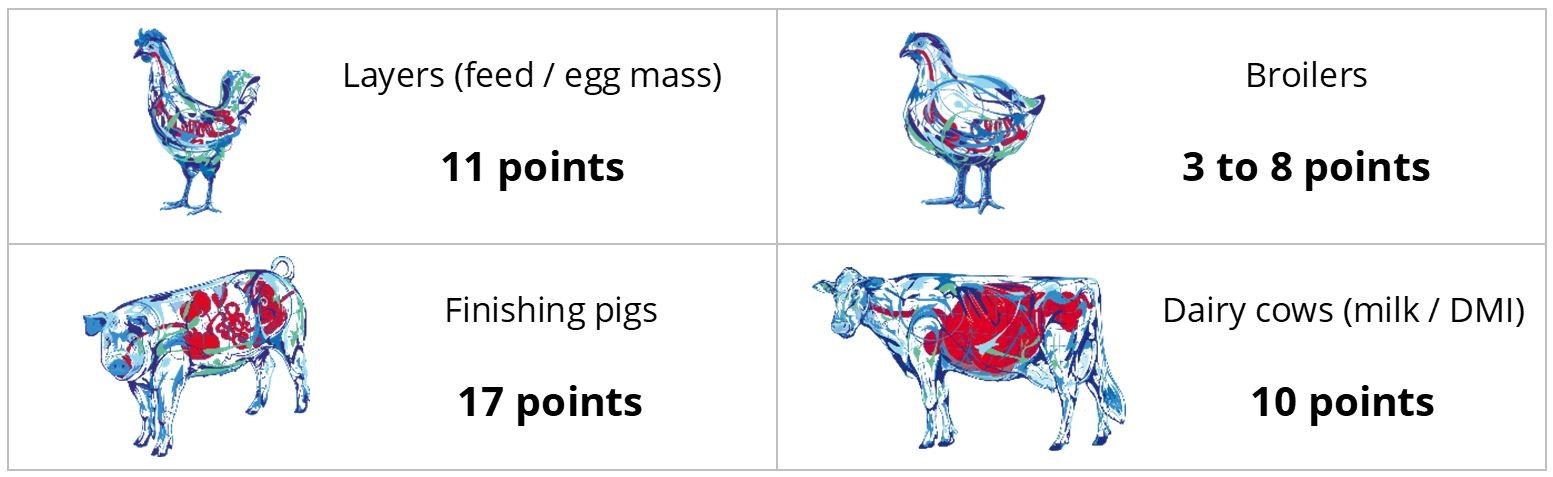

Feeding dairy cows with feed contaminated with mycotoxins can lead to a reduction in milk production. Milk quality may also deteriorate due to an adverse change in milk composition and mycotoxin residues, threatening the innocuousness of dairy products. Dairy farmers should therefore have feed tested regularly, consider masked mycotoxins, and take action. EW Nutrition’s MasterRisk tool provides a risk evaluation and corresponding recommendations for the use of products that mitigate the effects of mycotoxin contamination and, in the end, guarantee the safety of all of us.