Want better poultry performance? Focus on gut health

by Ruturaj Patil, Product Manager Phytogenic Liquids, EW Nutrition

Commercial poultry operations have undergone enormous changes in production practices over the last 50 years. Genetic selection for high production rates, along with upgraded management techniques and dietary measures, have led to increased performance standards in all poultry operations (Kogut et al., 2017). However, it is sensible to now look into whether poultry performance may soon reach a ceiling due to genetic and/or physiological limits. So, aiming at further performance optimization, poultry researchers and producers are now focusing on gut health.

Gut health management is key to sustainably improve poultry performance

The caveat, of course, is that, due to concerns about antimicrobial resistance, antimicrobial growth promoters (AGPs) no longer offer the easy answer to gut health issues they once were. To preserve antibiotics’ efficacy for cases where they are indispensable, gut health-oriented performance enhancement needs to come from other sources. This article reviews the principles of gut health management in poultry and shows how Activo liquid, a phytomolecules-based in-water solution, strengthens poultry performance by targeting gut health.

Gut health: the cradle of poultry performance

Gastrointestinal health in poultry birds encompasses three dimensions: microflora balance, gut structural integrity, and immune system status. The gut plays a vital and diverse role as it hosts most microorganisms in the body, contains more than twenty different hormones, digests and absorbs the nutrients, and accounts for 20% of body energy expenditure (Choct, 2021). When gut health is compromised, digestion and nutrient absorption are affected, with likely detrimental effects on feed conversion, followed by economic loss and greater disease susceptibility. Disease resistance and nutrient utilization largely depend on maintaining a beneficial gut antioxidant status, improving gut integrity, and modulating the gut microbiota (Oviedo-Rondón, 2019).

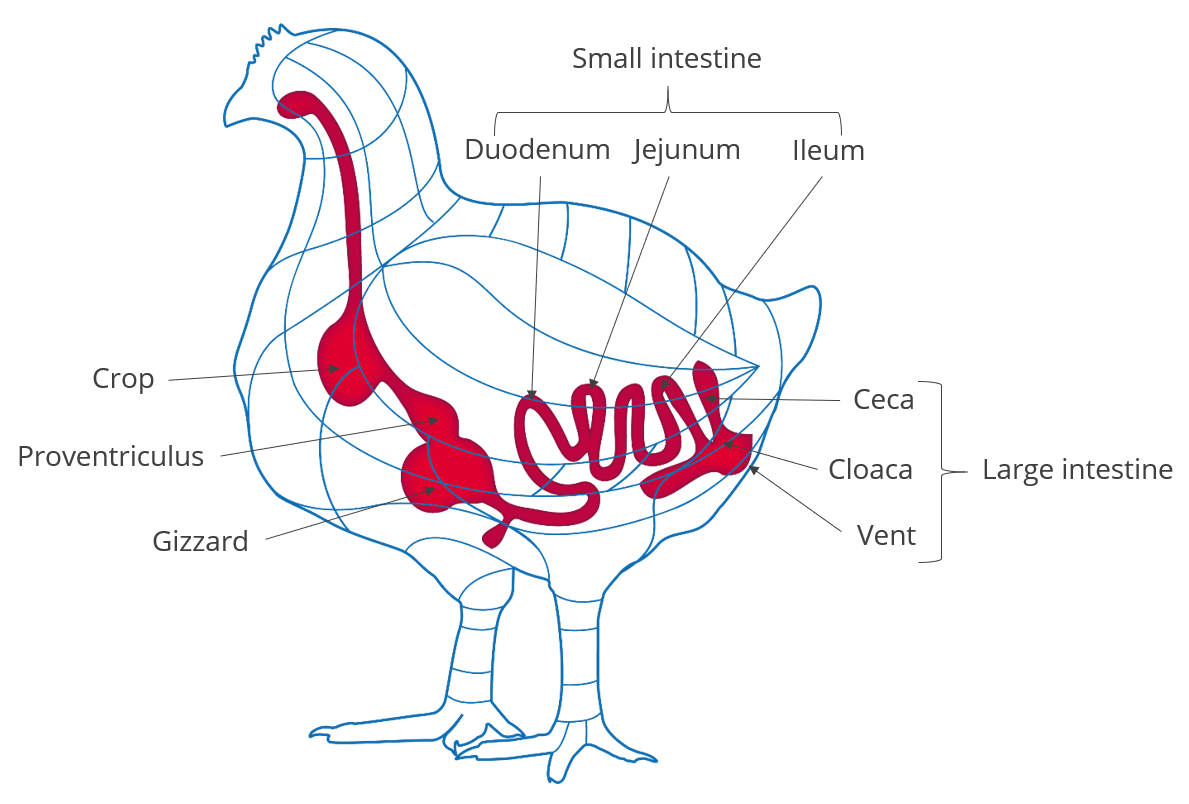

In birds, the gut is separated into five distinct regions (Figure 1): crop, proventriculus, gizzard, small intestine (duodenum, jejunum, and ileum), and large intestine (ceca, cloaca, and vent). Each of these regions has a specific role in the secretion of digestive juices and enzymes, the grinding of feed particles and then the digestion and absorption of nutrients (Bailey 2019).

Figure 1: Schematic overview of poultry gastrointestinal tract

Figure 1: Schematic overview of poultry gastrointestinal tract

Factors affecting gut health

Gut health is influenced by the balance between the physiological health status of host, the gut microbiota, and a range of specific factors, all of which producers need to consider. From a management perspective, key factors encompass deprived gut health, biosecurity, and production stress, which is elevated during certain critical stages (see table 1). Environmental factors include humidity, temperature, and ventilation. Dietary factors, such as feed and water quality, feed composition, and mycotoxin contamination, also impact the development and ongoing state of poultry birds’ intestinal microbiota.

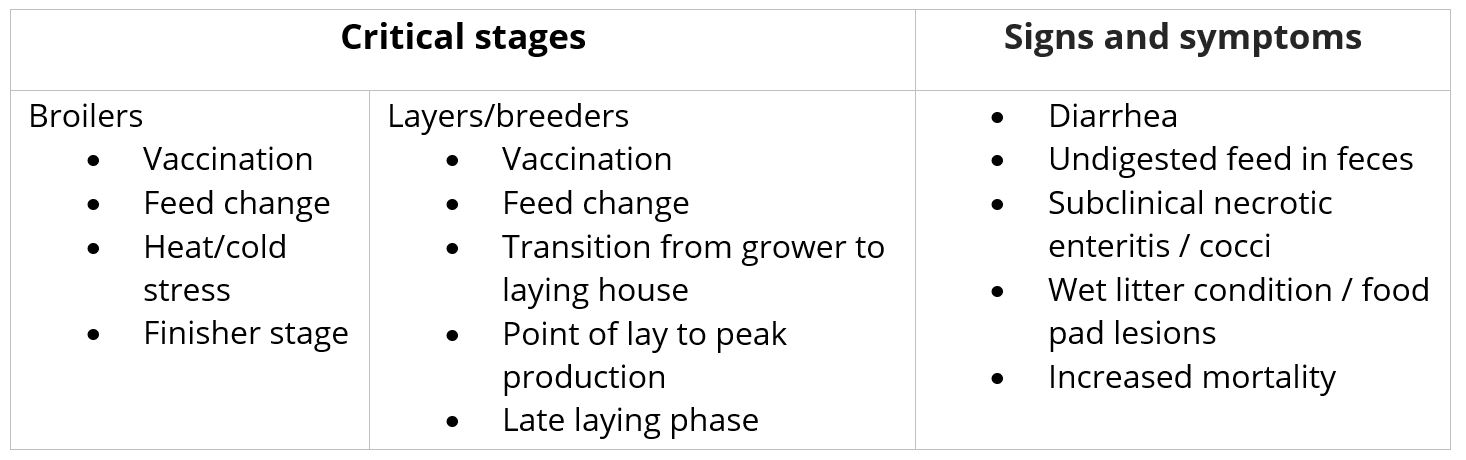

Table 1: Critical stages for gut health issues in poultry birds

Table 1: Critical stages for gut health issues in poultry birds

The future is here: antibiotic reduction through improved gut health

There is a strong trend towards antibiotic-free (ABF) poultry production, fueled by AGP bans in certain regions (such as the European Union) and increasing consumer interest in avoiding products containing traces of AGPs. ABF systems can be profitable as long as the prices for the final ABF products can cover the investment costs necessary to produce these products. Larger-scale, sustainable ABF production will depend on developing a more profound understanding of intestinal health alongside the development of practical applications that foster gut health throughout each step of the production system.

Feed additive solutions to support birds during challenging situations

Feed additive manufacturers are looking into accessible alternatives to mitigate the need for antibiotics in ABF systems, requiring enormous research and development efforts. At EW Nutrition, our approach is to offer a holistic antibiotic reduction program for gut health management in poultry. The program comprises feed- and water-based solutions to support gut health during high-challenge periods. Activo liquid, an in-water solution containing standardized amounts of selected phytomolecules, is a key component of our program. Based on its three-fold mode of action, Activo liquid provides gut health support that improves livability and feed efficiency:

- Antimicrobial activity hinders the growth of potential pathogens

- Better gut integrity and positive microbiota optimize feed efficiency and gut health

- Antioxidant activity at the gut level prevent free radical formation and oxidative stress

As a water-based solution, Activo liquid provides a quick and flexible option for gut health control on poultry farms. The benefits of Activo liquid supplementation have been demonstrated through several scientific and field studies globally.

Activo liquid reduces mortality and improves feed conversion in broilers

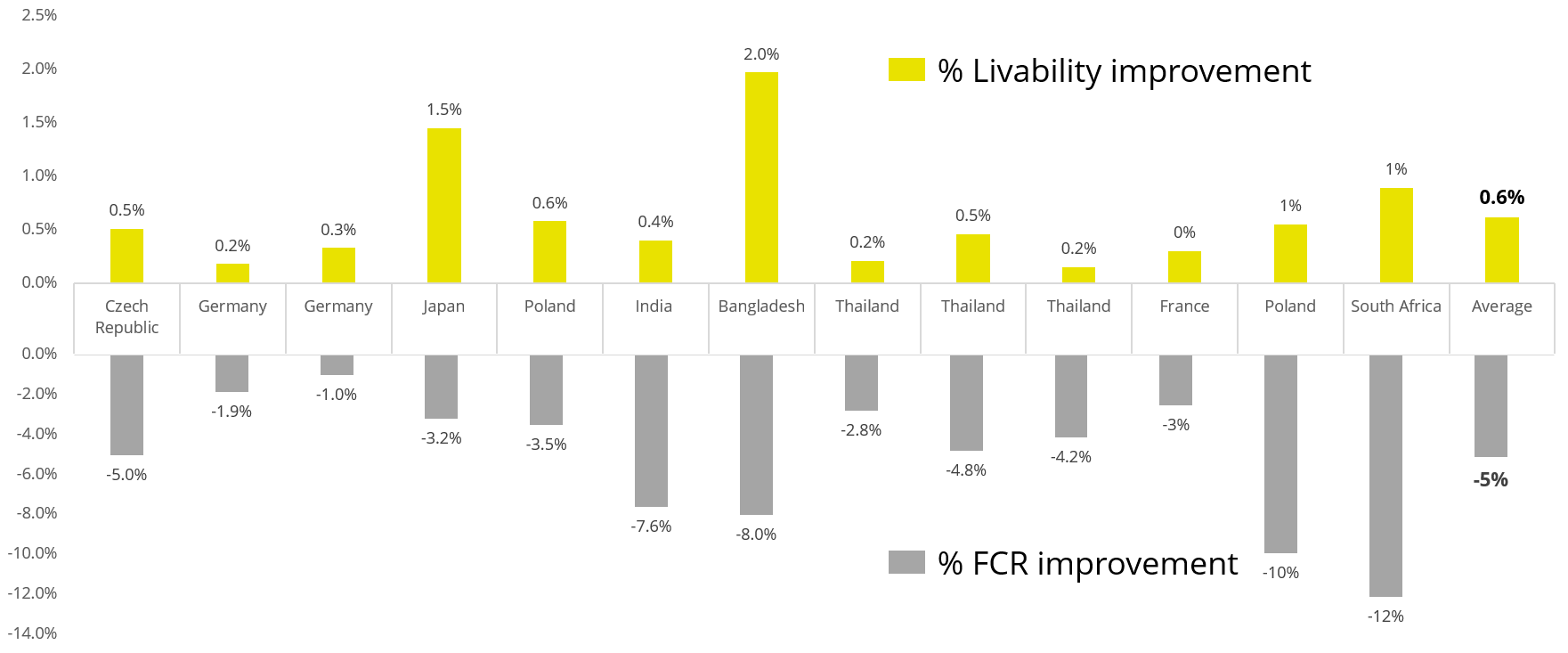

Numerous field studies for antibiotic-free broilers across different countries and breeds show: on average, the inclusion of Activo liquid reduces mortality by 0.6% and improves FCR by 5%, compared to non-supplemented control groups (Figure 2).

Figure 2: Changes in livability and feed conversion rate in Activo liquid-supplemented broilers

Figure 2: Changes in livability and feed conversion rate in Activo liquid-supplemented broilers

Activo Liquid supports broiler breeders from start of lay to pre-peak production

Broiler breeders are prone to gut-related issues from the start of lay to pre-peak production (age 24 to 32 weeks). This period is characterized by sudden changes in feed consumption and high production stress. Field studies from Thailand show that Activo liquid supplementation in this phase leads to improved livability and higher laying rates.

A of 34,000 female broiler breeders during the first 9 weeks of production found that for the group receiving Activo Liquid (200 ml / 1000 L, 5 days per week, 6 hours per day):

- The average laying rate/HH increased by 7.2 % during the trial period,

- Nearly 3 more hatching eggs per hen housed and about 5 more hatching eggs than the genetic standard were produced, and

- Mortality decreased by 0.2 % points compared to the control.

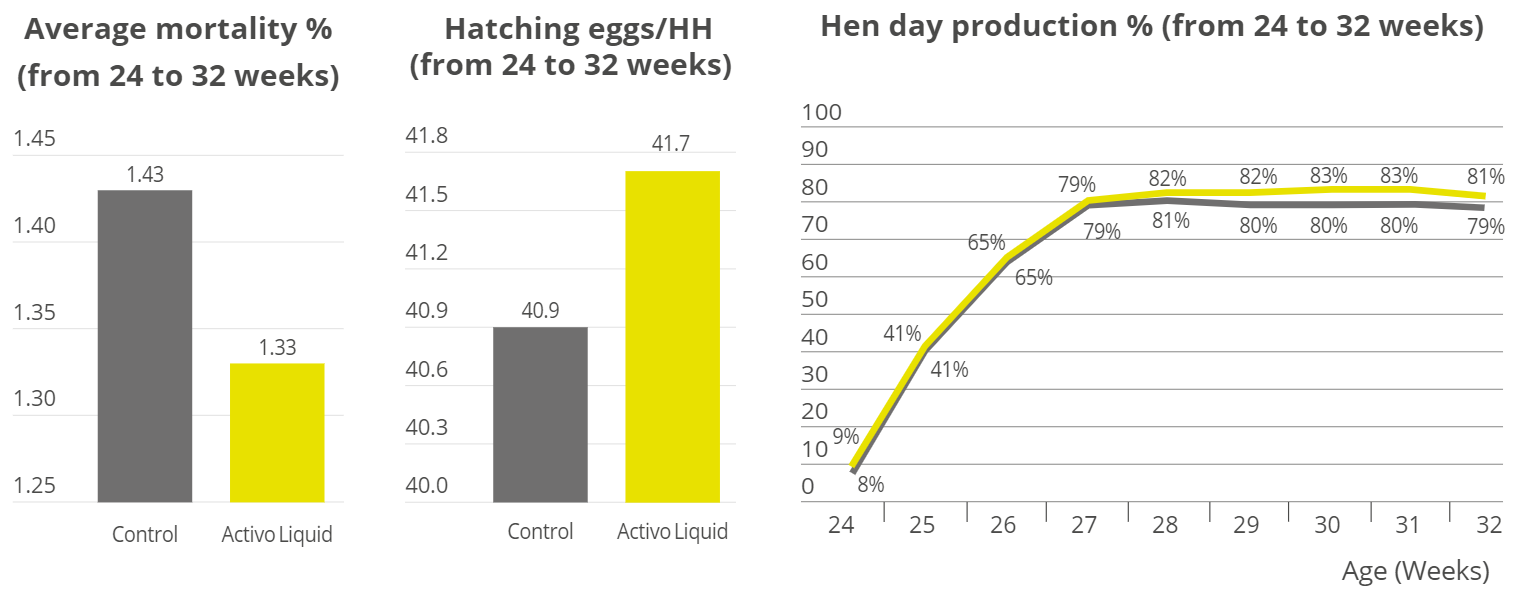

Another study, again evaluating the first 9 weeks of production using 20,000 birds, also found that broiler breeders supplemented with Activo Liquid show reduced mortality, a higher laying rate, and more hatching eggs per hen housed (Figure 3).

Figure 3: Performance results from Cobb broiler breeders, Activo liquid supplementation vs. control

Figure 3: Performance results from Cobb broiler breeders, Activo liquid supplementation vs. control

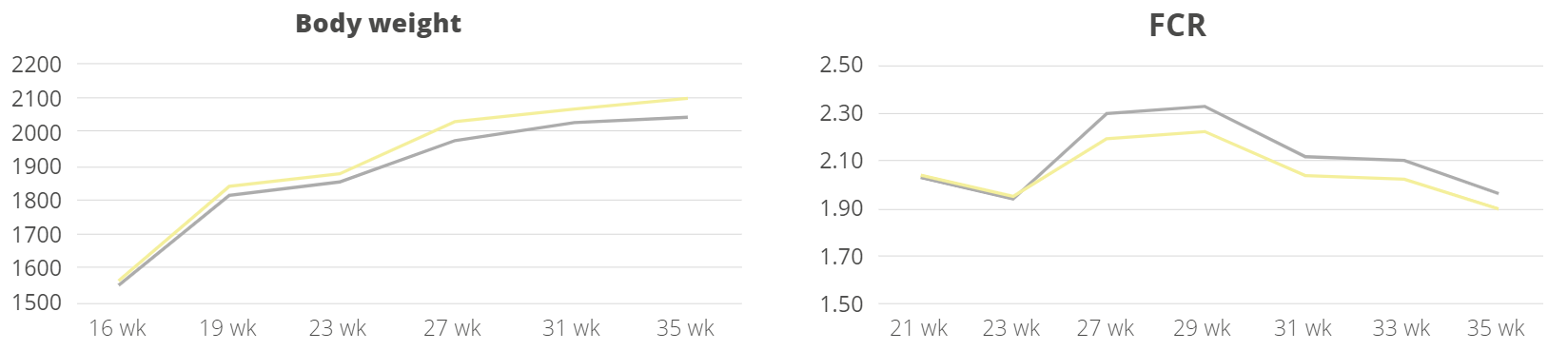

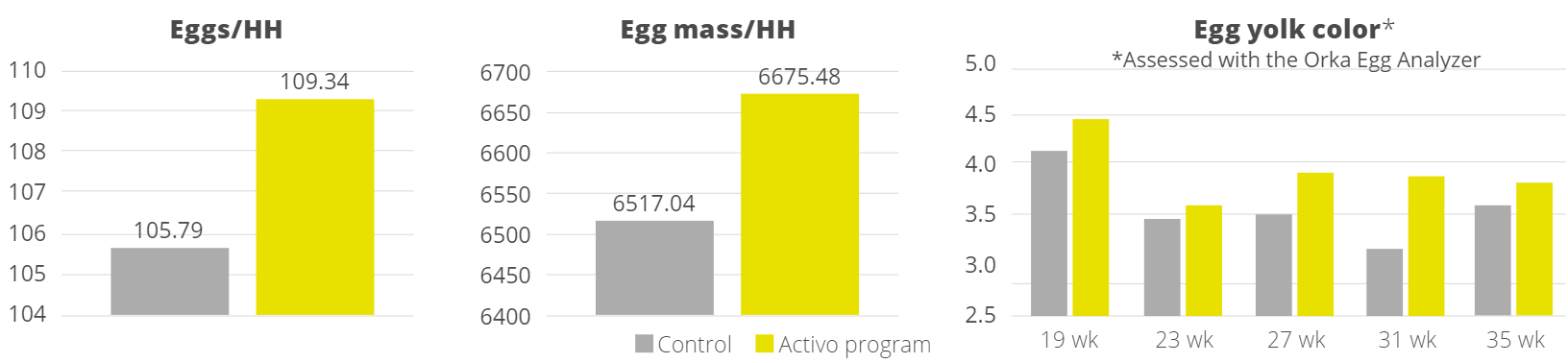

Activo program improves layer productivity

Commercial layers often becomes challenged due to stress originating from management issues, gut pathogens, and an improper assimilation of nutrients. The negative impact on gut health can result in poor uniformity, low livability, and impaired body weight gain. The Activo program (a combination of Activo powder and liquid) has been found to improve layer performance, likely because its phytogenic components foster better intestinal integrity and microbiome diversity.

A study of 8 replicates with 36 Hy-line brown laying hens was conducted in China, for instance, testing the inclusion of both Activo (100 g / MT of feed) and Activo Liquid (250 ml / 1000 L for 4 days, every 2 weeks, from week 15 to week 25). It found that the Activo program can effectively support the animals in coping with NSP-rich diets (Figure 4). Supplemented layers showed 3.36% higher egg production, representing more than 3.5 eggs and more than 150 grams of additional egg mass per hen housed during the period. Better gut health in the Activo Program gut was evidenced by a better hen body weight , as well as higher yolk color, lower FCR, and improved intestinal morphology parameters.

Figure 4: Performance results from Hy-line layers, Activo program vs. control

Figure 4: Performance results from Hy-line layers, Activo program vs. control

Conclusion: future improvements in poultry performance will come from the gut

As the trend towards ABF poultry production gains momentum, a concerted focus on supporting birds’ gut health is key to achieving optimal performance. Multiple field studies of Activo liquid application demonstrate that, due to their antimicrobial and antioxidant properties, the phytomolecules present in Activo liquid effectively support birds’ intestinal health during challenging periods.

In combination with good dietary, hygiene and management practices, phytomolecules offer a potent tool for reducing the use of antibiotics. The inclusion of Activo liquid in their birds’ diets allows poultry producers to achieve better gut health and, thus, stronger performance results in a sustainable way.

References

Bailey, Richard A. “Gut Health in Poultry: the World within – Update.” The Poultry Site, July 6, 2021. https://www.thepoultrysite.com/articles/gut-health-in-poultry-the-world-within-1.

Choct, Mingan. “The Importance of Managing Gut Health in Poultry.” Poultry Hub Australia, November 26, 2014. https://www.poultryhub.org/importance-managing-gut-health-poultry.

Kogut, Michael H., Xiaonan Yin, Jianmin Yuan, and Leon Bloom. “Gut Health in Poultry.” CAB Reviews: Perspectives in Agriculture, Veterinary Science, Nutrition and Natural Resources 12, no. 031 (October 1, 2017): 1–7. https://doi.org/10.1079/pavsnnr201712031.

Oviedo-Rondón, Edgar O. “Holistic View of Intestinal Health in Poultry.” Animal Feed Science and Technology 250 (2019): 1–8. https://doi.org/10.1016/j.anifeedsci.2019.01.009.