By Dr. Inge Heinzl, Editor, EW Nutrition

Eggs are an unparalleled source of nutrition for humans. Apart from being tasty and easy to cook, they are an essential ingredient for pasta, cakes, ice cream, and more. More importantly, they provide high-value proteins with amino acids we cannot produce, various B-vitamins, fat-soluble vitamins, and trace elements.

Assessing the value of the egg

The quality characteristics of eggs are usually divided into external features, such as:

· egg weight

· egg shape

· shell structure

· shell crack resistance

· dynamic shell resistance

· shell color

and internal characteristics, including:

· albumen weight

· Haugh unit (a measure of egg protein quality)

· yolk height,

· yolk diameter,

· albumen pH,

· yolk pH

· yolk color

For consumers, yolk color is probably the most important criterion for egg quality. Higher color intensity often is taken as indicating the good health of the laying hen.

Depending on the region or on the culture, people prefer more yellow or more orange yolks. In countries with traditional corn feeding, e.g., Mexico, they often like a deep yellow. In Northern Europe, consumers prefer a lighter yellow; in Southern Europe, more gold-orange yolks (see table 1).

| Country |

Yolk color fan value* |

| Belgium |

12-13 |

| Denmark |

9-10 |

| Finland |

9-10 |

| France |

11-12 |

| Germany |

11-14 |

| Greece |

11 |

| Italy |

12-13 |

| Netherlands |

7-9 |

| Austria |

12-14 |

| Portugal |

12-14 |

| Spain |

11-14 |

| Sweden |

9-10 |

| United Kingdom |

10-11 |

Table 1. Egg pigmentation preferences – variation across European countries

* Values range from 1 (very pale yellow) to 16 (intense orange)

Egg yolk color is achieved via feed

The typical color of the yolk depends on pigments that are ingested with the feed. Corn and alfalfa meal provide the yellow pigments lutein and zeaxanthin, belonging to the xanthophylls, a sub-group of carotenoids. The golden-orange color is provided by red pigments from chili or paprika (Grashorn, 2008). Egg yolks start changing color about 48 h after the application of xanthophylls.

To reach an optimal yolk coloration in egg production, diets should be supplemented with yellow and red xanthophylls. Yellow xanthophylls achieve a correct yellow base coloration. The main yellow pigments used in poultry feeding are apoester, a synthetic carotenoid, and saponified marigold extracts, a natural alternative containing lutein and zeaxanthin. For the redness, paprika or chili offer natural sources; canthaxanthin is a nature-identical red xanthophyll.

For a long time, synthetic colorants were the substances of choice in the poultry industry because they provide consistently predictable results and high product stability. However, consumers’ preferences concerning food have shifted; demand favors natural over synthetic food ingredients. Moreover, current EU regulations restrict these synthetic molecules’ inclusion level due to their potentially harmful effects on human health if applied in excessive doses.

| Carotenoid |

Maximum inclusion level |

| Apoester (ethyl ester of β-apo-8’-carotenoic acid) |

5 ppm |

| Canthaxanthin (β,β-Carotene-4,4′-dione) |

8 ppm |

Table 2. Maximum concentration allowed in feed for poultry production

Fortunately, there is already a natural, highly efficient option to replace apoester.

Lutein: a natural colorant, antioxidant, and provider of health benefits

One of these natural compounds is lutein, a lipophilic pigment. It is extracted from marigold petals, which contain up to 8.5 mg/g wet weight. Lutein is always accompanied by its isomer zeaxanthin.

Lutein – the yolk colorant

The use of xanthophylls such as lutein and zeaxanthin enables producers to safely control the color of the egg yolk and the broiler skin. In poultry, the carotenoids are deposited in high quantities in the epidermis, the fatty tissue, and the egg yolk. According to Grashorn (2016), between 4.4-23 % of dietary lutein and 23 % of dietary zeaxanthin are deposited in the egg yolk.

Lutein – the antioxidant protects the egg lipids

Another critical characteristic of lutein is its antioxidant effect. Egg yolks contain a high fat content. Therefore, they are very susceptible to lipid oxidation. Lutein, acting as an antioxidant, can prevent or at least limit lipid oxidation during egg processing. Kljak et al. (2021) compared different sources of pigments (basil, calendula, dandelion, marigold, and an industrial product containing canthaxanthin) concerning their antioxidant capacity. In this trial, marigold improved the yolks’ oxidative stability by 75 % compared to the control, with canthaxanthin showing no antioxidant effect. Kljak et al. attributed this effect to the carotenoids in the marigold extract.

Lutein – a value-added ingredient

Lutein and its isomer are nutritionally valuable and, therefore, welcome ingredients of the eggs. Once more, due to their antioxidant effects, they play an essential role in preventing and reducing cataracts and age-related eye dysfunctionalities in humans and animals (Landrum & Bone, 2001; Wang et al., 2016).

However, the amounts of antioxidant pigments in a standard egg are not very high (approx. 400 µg/egg). Compared to the total amount of antioxidants ingested, their importance for humans is only limited (Grashorn, 2008). The situation is different for functional eggs, which are widely sold in certain English-speaking countries. These eggs are enriched with n-3 fatty acids and with antioxidants such as ß-carotene (approx. 150 IE/egg).

Can natural pigments be as effective as synthetic apoester?

The precondition for the deposition of lutein in the egg or the skin is its absorption in the intestine. This absorption makes the difference between the synthetic apoester and the traditional yellow natural xanthophylls (lutein/zeaxanthin). In the case of traditional yellow xanthophylls, about three parts of the product are necessary to achieve the same effectiveness as one part of apoester.

With special technology owned by EW Nutrition, it is possible to improve the absorption of natural carotenoids and, therefore, the efficacy of lutein products. Only about 1.25 parts are then needed to replace one part of apoester.

Trial 1: A new generation of pigment products as effective as apoester

A trial was conducted in Spain to compare the effectiveness of apoester and a new generation natural pigment in combination with canthaxanthin.

For the trial, 288 layers (Hy-Line Brown, 39 weeks of age) were divided into 12 groups with 8 replications and 3 hens per replication. The trial consisted of a 7-week xanthophyll depletion and a 4-week experimental phase. The products included in the trial were a natural lutein product produced with a unique absorption-improving technology (Colortek Yellow, CTY), the synthetic xanthophyll apoester, and canthaxanthin. Three yolk color fan (YCF) targets were tested (10, 11, and 12).

For canthaxanthin, 1.5, 2.0, and 3.0 ppm were used. Within these groups of three different canthaxanthin concentrations, different concentrations of Colortek Yellow and apoester were applied to an otherwise xanthophyll-free diet:

| Group |

YCF target |

Ratio CTY/APO |

Yellow pigment source |

Dose yellow TX* (ppm) |

Dose red CTX** (ppm) |

| T1

T2

T3

T4 |

10 |

x 1.00

x 1.25

x 1.50 |

Apoester

CTY

CTY

CTY |

2.50

2.50

3.13

3.75 |

1.50 |

| T5

T6

T7

T8 |

11 |

x 1.00

x 1.25

x 1.50 |

Apoester

CTY

CTY

CTY |

2.50

2.50

3.13

3.75 |

2.00 |

| T9

T10

T11

T12 |

12 |

x 1.00

x 1.25

x 1.50 |

Apoester

CTY

CTY

CTY |

2.50

2.50

3.13

3.75 |

3.00 |

Table 3. Trial design | * TX= total xanthophylls | ** CTX = Canthaxanthin

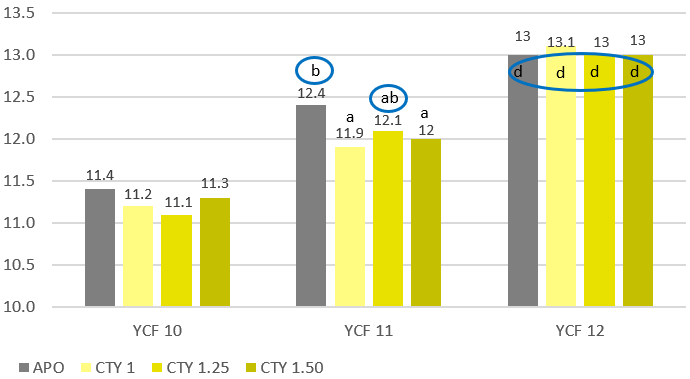

The colors of the egg yolks were measured with the help of the DSM egg yolk color fan.

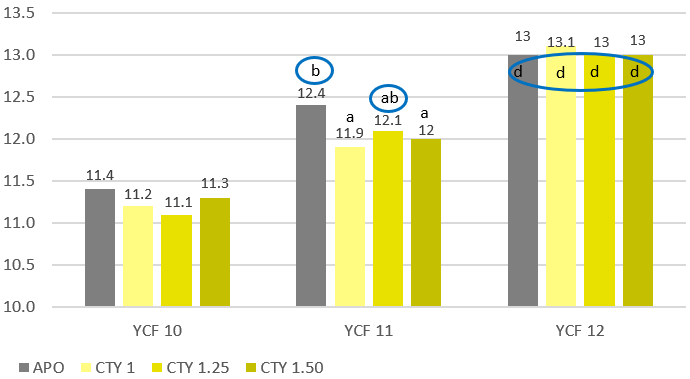

Figure 1 shows that Colortek Yellow at a 1.25 fold concentration as apoester (3.13 ppm) provided the same result as apoester regarding YCF target 11 (= canthaxanthin concentration of 2.00 ppm). In the case of YCF target 12 (= canthaxanthin concentration of 3.00 ppm), the same yolk color as apoester could be achieved using Colortek Yellow at a 1.25 or 1.5-fold concentration as apoester. Furthermore, it could be seen that the recommendations for apoester were overestimated and yielded color results 1 point above the target.

Figure 1. Egg yolk color values achieved by the use of apoester (APO) and different concentrations of Colortek Yellow (CTY)

* a, b, c, d: different superscripts mean statistical difference (P<0.05)

Can lutein be as stable as synthetic pigments like apoester?

Another potential disadvantage of natural pigments is lower stability. By accelerating saponification in a continuous process, producing a product with low moisture and a high content of xanthophylls is possible. This process leads to higher stability of the product and prolongs the shelf life.

Trial 2: New generation pigment shows better stability than apoester

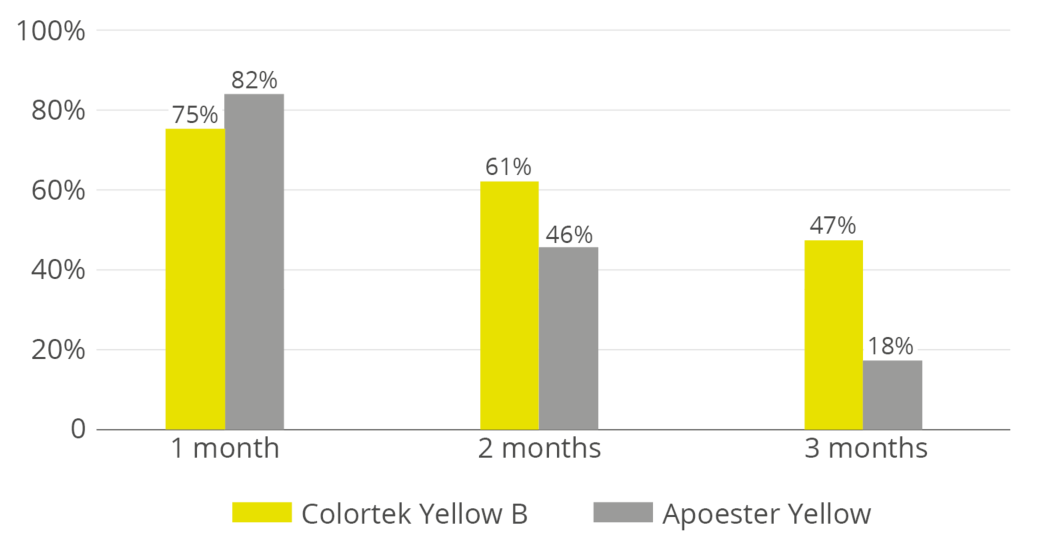

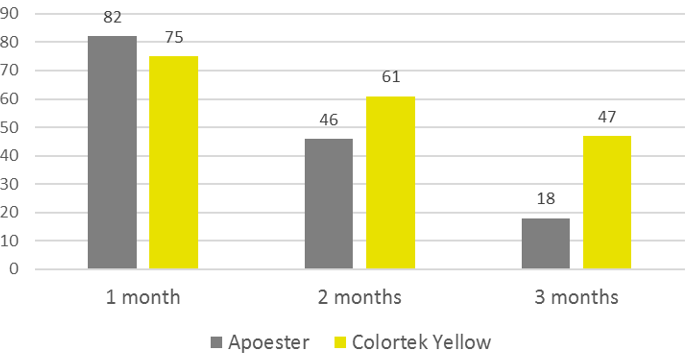

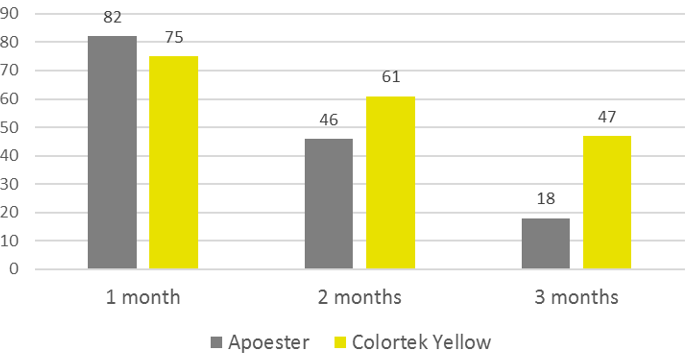

In this trial, the stability of products containing either a new generation natural colorant (Colortek Yellow) or apoester was tested. A vitamin-mineral premix containing 12.5 % choline chloride and one of the tested products were stored in closed bags at 30 °C and 75 % relative humidity. The recovery of the substances was tested after one, two, and three months.

The trial shows higher recovery rates for Colortek Yellow than for apoester at a longer storage time (Figure 2). This new technology, therefore, provides natural pigments with higher stability than products containing synthetic apoester.

Figure 2. Recovery rates of apoester and Colortek Yellow after different times of storage (%)

New-generation natural pigments beat traditional synthetic options

The trend towards natural food ingredients also affects egg yolk color: consumers want natural alternatives to get their preferred yolk color, and regulators are imposing ever stricter limits on synthetic additives. Natural pigments have historically had two limiting characteristics compared to synthetic ones, their lower absorption and their lower stability. Due to new technologies, natural pigmentation products such as Colortek Yellow can now offer absorption rates comparable to apoester and even higher stability – making them the optimal replacement for synthetic colorants.

References

Grashorn, M. “Eiqualität.” In Legehuhnzucht und Eiererzeugung. Empfehlungen für die Praxis (special issue 322) edited by W. Brade, G. Flachowsky, and L. Schrader, 18-33. Landbauforschung – vTI Agriculture and Forestry Research, 2008

Grashorn, M. “Feed additives for influencing chicken meat and egg yolk color.” In Handbook on Natural Pigments in Food and Beverages. Industrial Applications for Improving Food Color, edited by R. Carle and R.M. Schweiggert, 283-302. Woodhead Publishing, 2016.

https://doi.org/10.1016/C2014-0-03842-7

Kljak, K., K. Carović-Stanko, I. Kos, Z. Janječić , G. Kiš, M. Duvnjak, T. Safner, and D. Bedeković. “Plant carotenoids as pigment sources in laying hen diets: effect on yolk color, carotenoid content, oxidative stability and sensory properties of eggs.” Foods 10, no. 4 (2021):721

https://doi.org/10.3390/foods10040721

Landrum, J. T. and R.A. Bone. “Lutein, zeaxanthin, and the macular pigment.” Archives of Biochemistry and Biophysics 385 no. 1 (2001): 28–40.

https://doi.org/10.1006/abbi.2000.2171.

Wang, W., J., C. Moore, J. Jackson, and K. Narfström. “Antioxidant supplementation increases retinal responses and decreases refractive error changes in dogs.” J. Nutr. Sci. 5 e18 (2016): 7 pages

http://dx.doi.org/10.1017/jns.2016.5