Recent advances in energy evaluation in pigs

Conference Report

During the recent EW Nutrition Swine Academies in Ho Chi Minh City and Bangkok, Dr. Jan Fledderus, Product Manager and Consultant at Schothorst Feed Research, discussed that much money is involved in a correct energy evaluation system. “Net energy is 70% of feed costs, and feed is about 70% of total costs.” Therefore, an accurate energy evaluation system is important as it will give:

- Flexibility to use different raw materials

- Reduction of formulation costs

- Best prediction of pig performance

- Match the available dietary energy requirement of the feed to the pig’s requirement

Energy evaluation systems for pigs

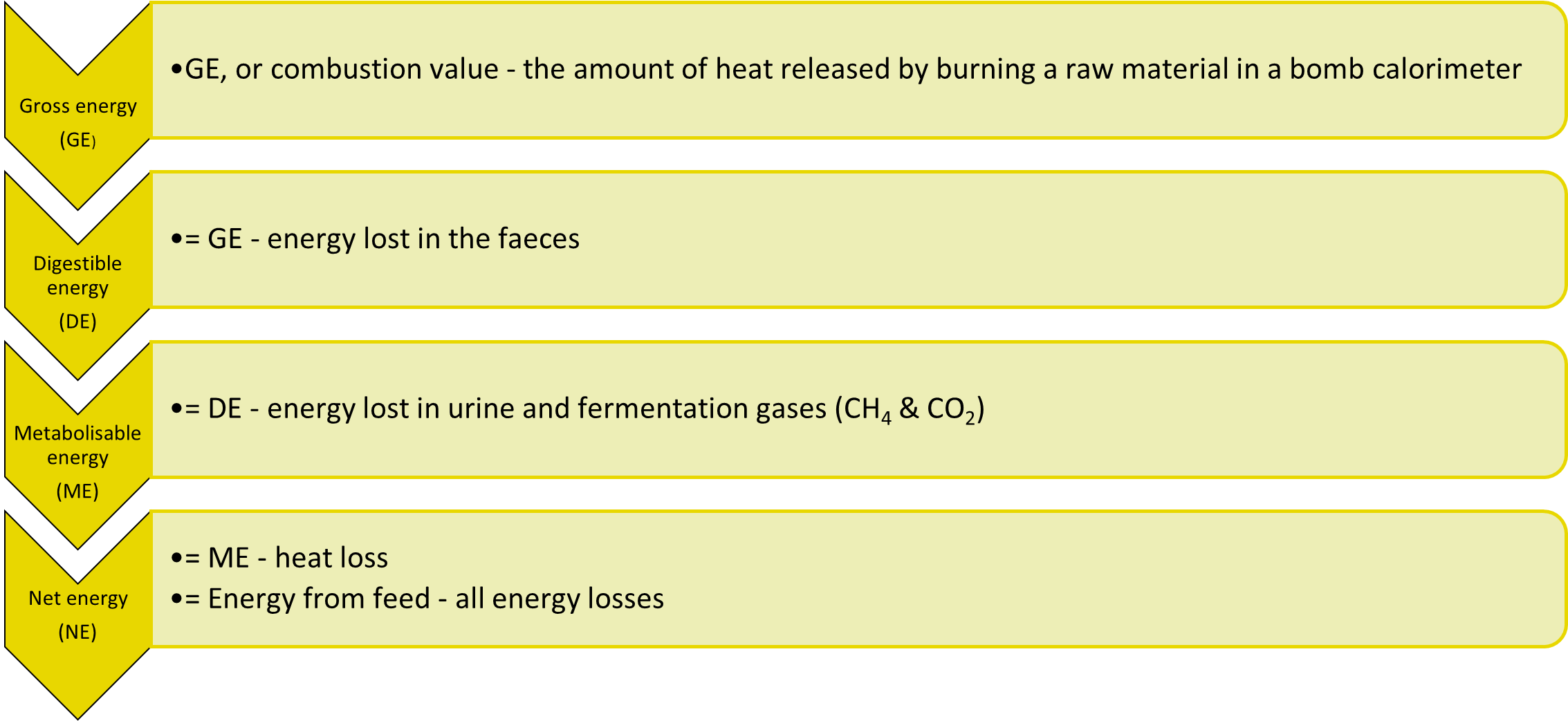

The energy value of a raw material or complete feed can be expressed using different energy evaluation systems. Net energy (NE) in pigs refers to the amount of energy available for maintenance and production after accounting for energy losses during digestion, metabolism, and heat production. It is a crucial concept in swine nutrition as it provides a more accurate measure of the energy value of feed ingredients compared to other systems like digestible energy (DE) and metabolizable energy (ME). Diets formulated using NE are lower in crude protein than those using DE or ME because the heat lost during catabolism and excretion of excess nitrogen is considered in the NE system.

Effect of energy

Energy is derived from three nutrients: lipids (fats and oils), carbohydrates, and proteins. Using NE values instead of DE or ME values can lead to changes in ingredient ranking when formulating diets. For example:

- Ingredients high in fat or starch may be undervalued in DE systems but receive appropriate recognition in NE evaluations.

- Conversely, protein-rich or fibrous ingredients may be favored in DE systems.

Table 1: Energy values (kcal/kg) of nutrients

| Nutrient | Energy | Starch | Protein | Fat |

|---|---|---|---|---|

| Gross energy | GE | 4,486 (100) | 5,489 (122) | 9,283 (207) |

| Digestible energy | DE | 4,176 (100) | 4,916 (118) | 8,424 (202) |

| Metabolizable energy | ME | 4,176 (100) | 4,295 (103) | 8,424 (202) |

| Net energy | NE | 3,436 (100) | 2,434 (71) | 7,517 (219) |

| Heat production (kcal/kg) | 740 | 1,861 | 907 | |

| Heat production (% of NE) | 22% | 76% | 12% | |

Calculation of net energy

Net energy (kcal/kg dry matter) is calculated as:

= 2,577 x digestible crude protein

+ 8,615 x digestible crude fat

+ 3,269 x ileal digestible starch

+ 2,959 x ileal digestible sugars

+ 2,291x fermentable carbohydrates

Factors affecting nutrient digestibility

This raises the obvious question, ‘What is the nutrient digestibility of your raw materials?’ Dr. Fledderus considered several factors that affect nutrient digestibility and, therefore, NE values, including

- Age: as pigs grow, their digestive systems mature, leading to improved nutrient digestibility. Younger pigs typically have lower digestibility rates due to an underdeveloped gastrointestinal tract. Older pigs typically exhibit higher digestibility, especially for fibrous diets, as their digestive systems become more efficient at breaking down complex nutrients.

- Physiological stage: the digestibility of diets can vary between pregnant and lactating sows. Digestibility is generally higher for gestating sows; lactating sows may have slightly lower digestibility due to higher feed intake. Also, lactating sows do not consume enough feed to meet their energy needs, leading to body tissue mobilization and weight loss.

- Feed intake and number of meals per day: Increased feed intake and more frequent meals can enhance nutrient digestibility. Regular feeding helps maintain gut motility and reduces the risk of digestive disturbances. Studies indicate that pigs fed multiple smaller meals exhibit better nutrient absorption than those fed larger meals less frequently.

- Use of antibiotics and feed additives: including exogenous enzymes and other additives can improve nutrient breakdown and overall digestibility of complex feed components, further influencing ingredient rankings within different energy evaluation systems. Antibiotics can lead to dysbiosis, negatively impacting overall gut health and digestion.

- Feed processing: gelatinized starch is more easily broken down by digestive enzymes, resulting in higher and faster digestibility compared to raw or unprocessed starch. This increased digestibility leads to a greater proportion of energy being absorbed in the small intestine, contributing positively to the NE value of the feed. As the particle size of feed ingredients decreases, the NE increases. While smaller particles generally improve digestibility, excessively fine grinding can lead to adverse effects such as increased risk of gastric ulcers in pigs.

- Intestinal health: a healthy gut is crucial for optimal nutrient absorption. Factors such as the presence of beneficial microbiota and the integrity of the intestinal barrier play significant roles in nutrient digestibility. Conditions like inflammation or dysbiosis can impair nutrient absorption and decrease overall performance.

NE system shows better the “true” energy of the diet

Dr. Fledderus concluded that the NE system offers a closer estimate of pigs’ “true” energy available for maintenance and production (growth, lactation, etc.). This leads to better ingredient rankings, reduced crude protein levels, which decreases nitrogen excretion, and enhanced nutrient utilization, contributing to more sustainable pig production practices. This aligns with increasing demands for environmentally responsible farming methods.

EW Nutrition’s Swine Academy took place in Ho Chi Minh City and Bangkok in October 2024. Dr. Jan Fledderus, Product Manager and Consultant at the S&C team at Schothorst Feed Research, one of the founders of the Advanced Feed Package and with a strong focus on continuously improving the price/quality ratio of the diets for a competitive pig sector, was a reputable guest speaker in these events.