by Technical Team, EW Nutrition

In light of climatic challenges, variability in raw material quality and technical constraints, it can be challenging for feed manufacturers to optimize the water content in compound feed.

In combination with high temperatures, too much moisture in feed can favor the growth of mold. Molds spoil feed by depleting energy and nutrients and rendering the feed unpalatable. Even worse, some molds release toxins harm animals’ health and performance. On the other hand, too little moisture in feed has a negative impact on feed digestibility and pellet durability, increasing the level of fines, process loss and energy consumption, while decreasing press yield (Moritz et al., 2002).

In this article, we look at how the right choice of processing aid is key to sustainably boosting feed mill efficiency. A concerted focus on moisture management when preconditioning the mash feed prior to pelleting allows feed producers to reap both economic and feed quality benefits.

Why moisture management requires both surfactants and organic acids

Moisture management starts with monitoring certain indicators. The moisture content measures the total amount of water contained in a substance, usually expressed as a percentage of the total weight. Feed manufacturers track the moisture contents of raw materials, mash feed, and pellets during all processing stages to optimize quality, yields, and profitability.

For the purpose of preventing mold growth, however, another indicator is even more critical: water activity (aw) is technically defined as the ratio of partial vapor pressure of water in a substance to the partial vapor pressure of pure water under the same temperature and pressure conditions. What this captures is the energy state of water in a substance, i.e. its potential for (bio)chemical activity, including the growth of bacteria, yeasts, and molds. Simply put, microorganisms will usually not grow below a certain water activity level, and the higher the water activity, the higher the chance of microbial growth (Roos, 2003).

Minimum water activity (aw) for growth and toxin production of toxigenic fungi affecting grains

|

|

Minimum aw |

| Fungal species |

Mycotoxin |

Growth |

Toxin production |

| Aspergillus flavus |

Aflatoxin |

0.78 – 0.84 |

0.84 |

| Aspergillus parasiticus |

0.84 |

0.87 |

| Aspergillus ochraceus |

Ochratoxin |

0.77 |

0.85 |

| Penicillium aurantiogriseum |

0.82 – 0.85 |

0.87 – 0.90 |

| Penicillium viridicatum |

0.80 – 0.81 |

0.83 – 0.86 |

| Aspergillus ochraceus |

Penicillic acid |

0.77 |

0.88 |

| Penicillium aurantiogriseum |

0.82 – 0.85 |

0.97 |

| Penicillium patulum |

Patulin |

0.81 |

0.95 |

| Penicillium expansum |

0.82 – 0.84 |

0.99 |

| Aspergillus clavatus |

− |

0.99 |

| Fusarium verticillioides |

Fumonisins |

0.88 |

0.93 |

| Fusarium proliferatum |

0.88 |

0.93 |

Adapted from Magan, Aldred, and Sanchis (2004)

Can we condition feed with pure water?

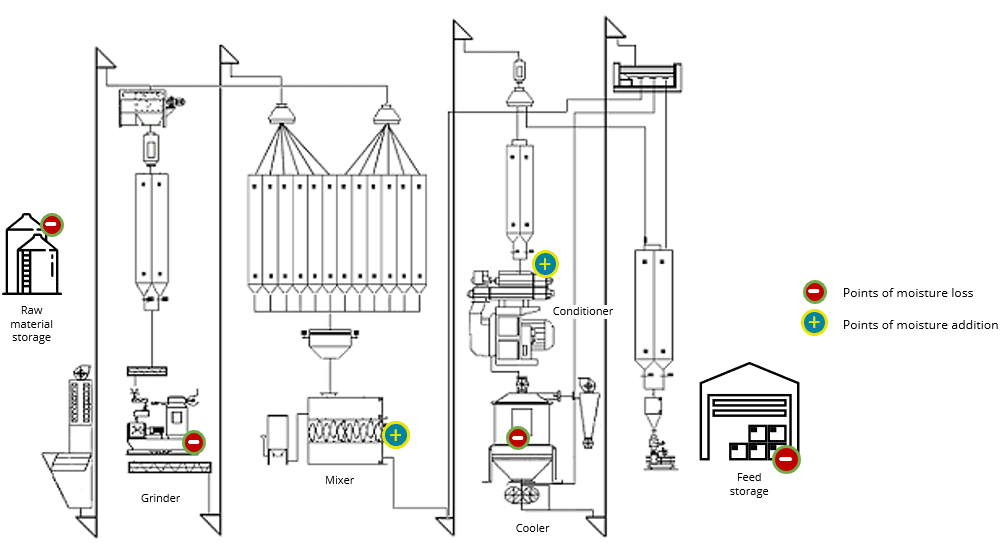

Why does this matter? The intense friction during grinding and mixing results in heat; subsequently, moisture from the mash feed is lost in the form of vapor. These losses need to be mitigated, when the feed is too dry, the milling equipment cannot function optimally and the pellet quality deteriorates. However, simply adding water does not work well: Pure water does not readily bind to the feed; it effectively “sits on top” of the feed surface, increases the feed’s water activity and thus becomes a perfect substrate for microbial growth. Plus, pure water steam largely evaporates again when the feed is cooled.

Surfactants

Hence, at the conditioning phase, it is critical to add surfactants to the hydrating solution. Surfactants change the way water behaves: by reducing the surface tension of water, they enable the feed particles to absorb the water and ensure that it is evenly distributed throughout the feed. There are numerous beneficial effects as improved moisture retention

- facilitates the starch gelatinization during conditioning (important for pellet digestibility and durability),

- minimizes feed shrinkage at the cooling stage,

- reduces friction and hence the energy required for the pellet die (improving milling efficiency), and

- curbs microbial growth by reducing water activity.

While surfactants contribute to mold control, feed manufacturers also require the help of organic acids to optimize the moisture content in feed while reliably preventing mold (re)contamination hazards along the distribution chain.

Organic acids

Let us consider how the most effective one, propionic acid, works: In its non-dissociated state, propionic acid has all its hydrogen ions attached to the molecule. Once it enters a mold cell, the propionic acid dissociates, meaning the hydrogen ions separate from the molecule. They reduce the intracellular pH in the mold cell and inhibit its metabolic pathways, ultimately leading to cell death (Smith et al., 1983).

Common feed ingredients such as soybean meal, maize, wheat, barley, and dehulled oats are often stored for several months. Given variable and likely challenging temperature, oxygen, and moisture conditions, their water activity levels can easily escalate (Mannaa and Kim, 2017) – rendering the long-lasting anti-fungal activity of targeted organic acid preconditioning even more important.

SURF•ACE: Improve mill performance and pellet quality

A synergistic blend of organic acids and surfactants can achieve the objective of adding moisture without risking either the subsequent loss of moisture during cooling or the development of mold. This is the working principle behind SURF•ACETM feed mill processing aid, carefully formulated to best achieve the dual objective of higher feed quality and higher production efficiency. This objective is achieved in concordance with optimal resource use and lower energy requirements, thus also contributing to the feed industry’s environmental commitments.

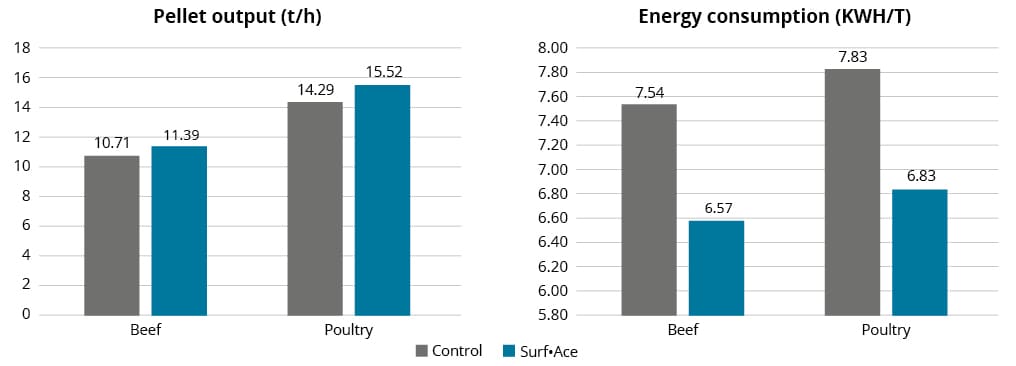

Improved press yield

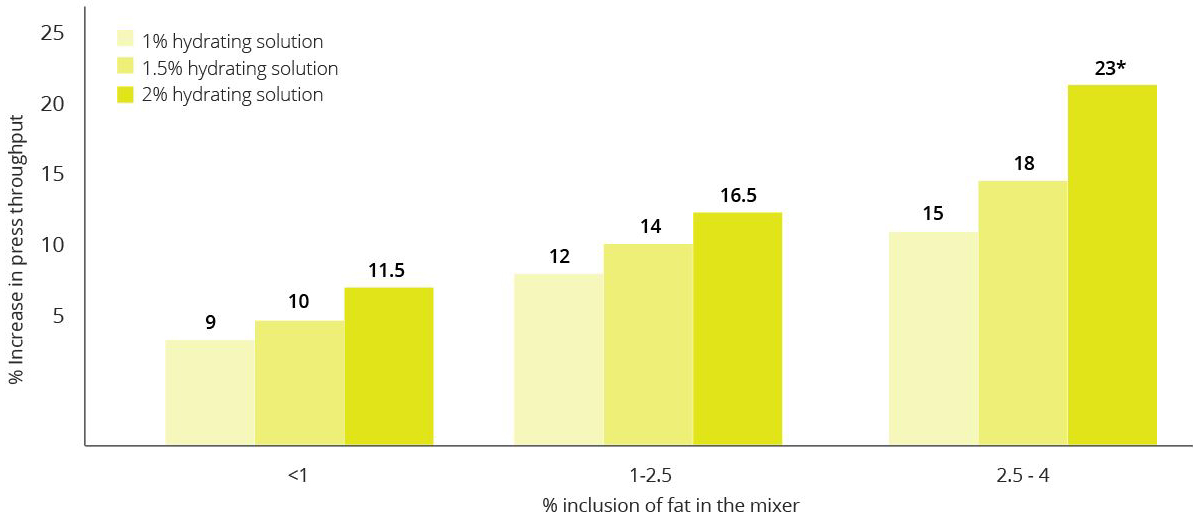

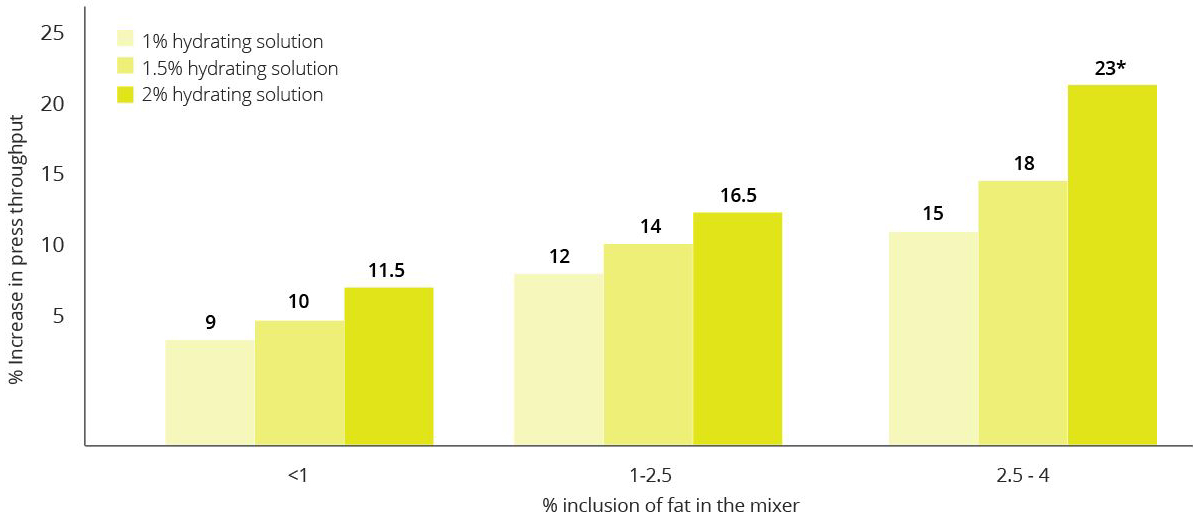

The effect of adding SURF•ACE to diets with increasing levels of fat were evaluated at more than 40 feed mills, with production capacities ranging from 5 to 20 tons per hour, under identical electricity consumption conditions. The results show that the addition of SURF•ACE to the preconditioning solution increases press throughout (t/h), relative to pure water preconditioning, by between 9 and 23 %, depending on how much preconditioning solution is applied and the level of fat in the diet:

Addition of SURF•ACE increases press throughput

*Including large volumes of hydrating solution in high-fat diets might adversely affect the durability values of the feed

What is the role of fat in this scenario? Dietary fat acts as a lubricant between the feed and the pellet die, reducing the pressure within the die. The higher the percentage of fat included in the mixer, the lower the energy required to process the mash (Pope, Brake, und Fahrenholz, 2018). The surfactants contained in SURF•ACE have an emulsifying effect; they help bind water to the fat element of the feed. The emulsion of water and fat “behaves” like fat, improving the lubrication of press and generating a higher throughput for the same electricity consumption.

Higher pellet quality

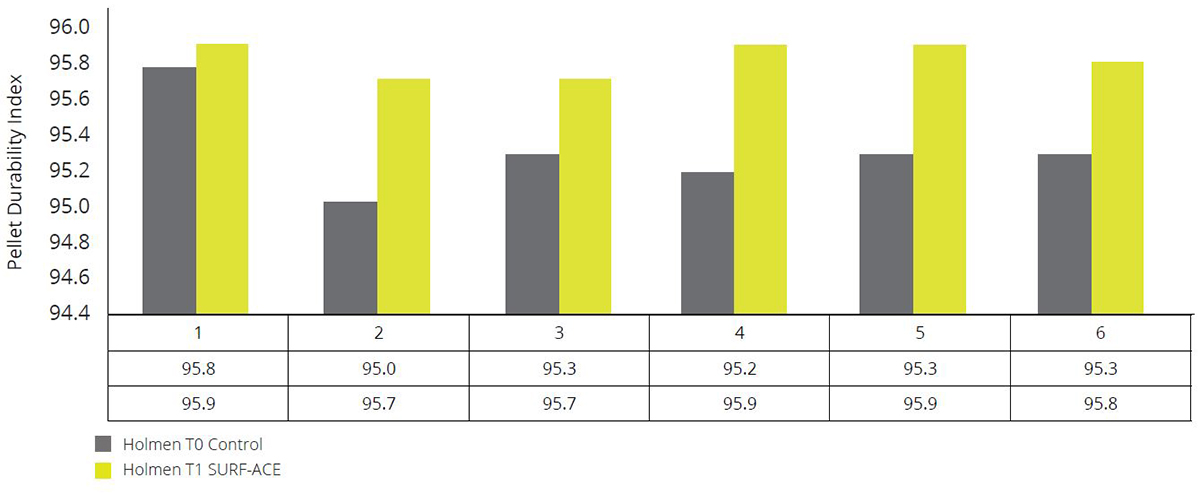

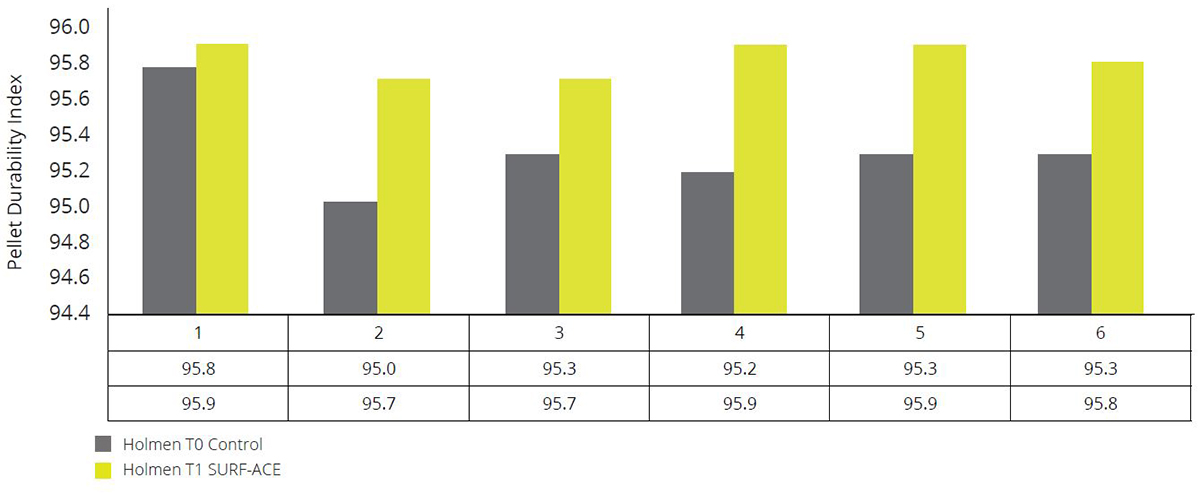

Importantly, adding SURF•ACE does not negatively affect pellet durability, a common issue in high-fat diets (Moritz et al., 2003). On the contrary, it enhances pellet durability as more crystal starch becomes gelatinized. This translates into improved results for Holmen pellet durability testing:

Addition of SURF•ACE improves pellet durability

Pellets need to withstand significant pneumatic handling, for example, during bagging and transport, and in the feed lines. The Holmen durability tester simulates this handling, and calculates the percentage of fine generated, expressed as a pellet durability index (PDI). Across six different poultry compound feed types, SURF•ACE improves pellet quality and thus the PDI. Fewer fines equate to less reprocessing for feed manufacturers and higher palatability for animals.

The next level in compound feed production

Achieving optimal moisture levels in compound feed is a complex balancing act involving technical constraints, raw material variability, microbial challenges, and the price pressures of competitive feed markets. Feed mills generally operate within a particular comfort zone, a throughput and quality level at which they minimize production problems. Thanks to its dual surfactant and preservative effects, SURF•ACE feed mill processing aid expands the comfort zone in two dimensions: From an economic point of view, the improved lubrication gives mills the choice of either pushing their performance levels closer to their equipment’s potential capacity or achieving the same results at lower electricity use. From a feed quality angle, effective mold prevention and improved pellet quality allow for safer, more palatable feed – and from there we come full circle, to safe, nutritious food for all of us.

References

Magan, Naresh, David Aldred, and Vicente Sanchis. “The Role of Spoilage Fungi in Seed Deterioration.” Essay. In Fungal Biotechnology in Agricultural, Food, and Environmental Applications, edited by Dilip K. Arora, 311–23. New York: Marcel Dekker, 2004.

Mannaa, Mohamed, and Ki Deok Kim. “Influence of Temperature and Water Activity on Deleterious Fungi and Mycotoxin Production during Grain Storage.” Mycobiology 45, no. 4 (2017): 240–54. https://doi.org/10.5941/myco.2017.45.4.240.

Moritz, J. S., K. J. Wilson, K. R. Cramer, R. S. Beyer, L. J. McKinney, W. B. Cavalcanti, and X. Mo. “Effect of Formulation Density, Moisture, and Surfactant on Feed Manufacturing, Pellet Quality, and Broiler Performance.” Journal of Applied Poultry Research 11, no. 2 (2002): 155–63. https://doi.org/10.1093/japr/11.2.155.

Moritz, J. S., K. R. Cramer, K. J. Wilson, and R. S. Beyer. “Feed Manufacture and Feeding of Rations with Graded Levels of Added Moisture Formulated to Different Energy Densities.” Journal of Applied Poultry Research 12, no. 3 (October 1, 2003): 371–81. https://doi.org/10.1093/japr/12.3.371.

Pope, J. T., J. Brake, and A. C. Fahrenholz. “Post-Pellet Liquid Application Fat Disproportionately Coats Fines and Affects Mixed-Sex Broiler Live Performance from 16 to 42 d of Age.” Journal of Applied Poultry Research 27, no. 1 (March 1, 2018): 124–31. https://doi.org/10.3382/japr/pfx054.

Roos, Y. H. “WATER ACTIVITY | Effect on Food Stability.” Essay. In Encyclopedia of Food Sciences and Nutrition Second Edition, edited by Luiz Trugo and Paul M. Finglas, 6094–6101. Cambridge, MA: Academic Press, 2003.

Smith, Philip A., Talmadge S. Nelson, Linda K. Kirby, Zelpha B. Johnson, and Joseph N. Beasley. “Influence of Temperature, Moisture, and Propionic Acid on Mold Growth and Toxin Production on Corn.” Poultry Science 62, no. 3 (1983): 419–23. https://doi.org/10.3382/ps.0620419.

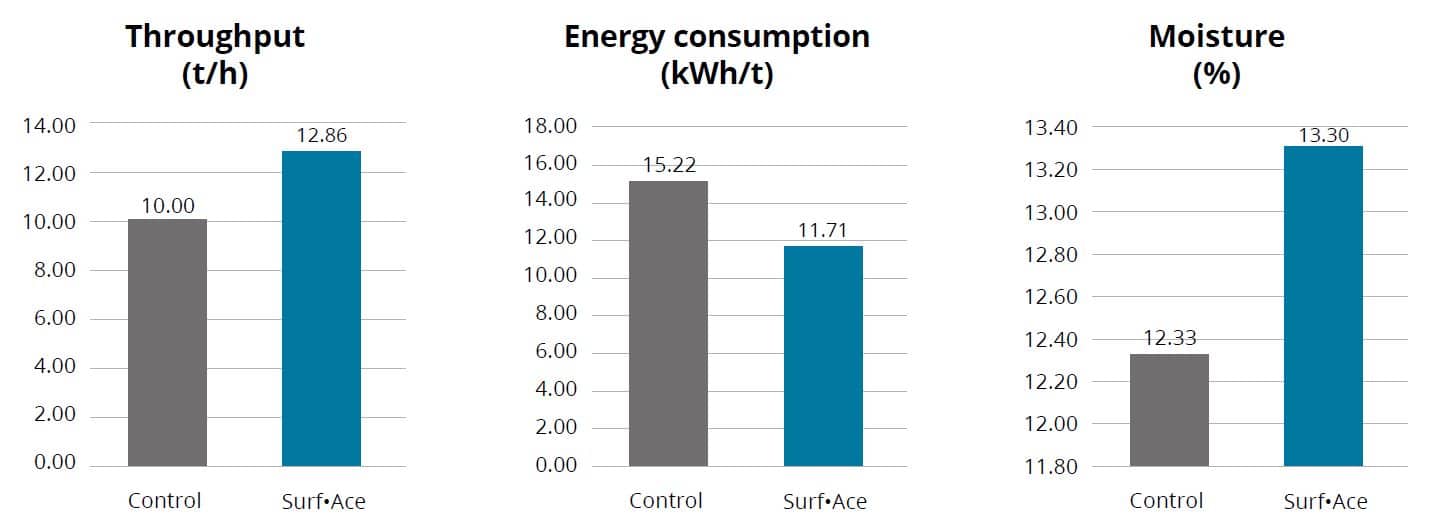

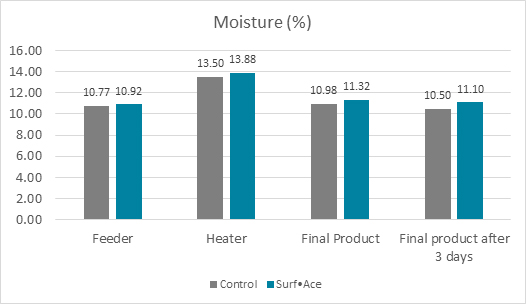

Figure 2: Surf-Ace achieved higher moisture levels in different phases of the feed production process

Figure 2: Surf-Ace achieved higher moisture levels in different phases of the feed production process Figure 3: Surf-Ace provided for higher moisture content in the feed

Figure 3: Surf-Ace provided for higher moisture content in the feed