by Inge Heinzl, Editor, Marisabel Caballero, Global Technical Manager Poultry, and Ajay Bhoyar, Global Technical Manager Poultry, EW Nutrition

In the last few months, the prices for feed grains and oilseeds such as soybeans have been climbing to multi-year heights. In part, this can be explained by high corn purchases by China and increasing export duties in Russia. The most significant cause, however, are weather events in producing countries: Just in the last year, droughts in the USA, Canada, and France raised the price of wheat by 40 %, the worst La Niña climate event in 91 years and the drought in China’s biggest corn-growing area made corn about 100 % more expensive, and soybeans carry a 40 % higher price tag because of dry conditions in Argentina.

These events are a stark reminder that for global agriculture climate change impacts are already a reality. High feed costs are an enormous challenge for the whole agricultural sector and sustainable strategies need to be adopted to enable a more efficient use of resources, both in the short and long term. This article explores possibilities to cope with the current situation. Through understanding the positions of farmers, integrators and feed millers and using targeted feed additive solutions, we can achieve a responsible use of resources that makes animal production more resilient to feed price increases.

Feed cost issues? Always start with this

The first question producers need to ask themselves is always if there is any step in the production process that could be done more effectively. Similar to biosecurity programs, the basic steps seem self-evident, but to consistently implement them in the complex on-farm reality requires regular checks.

Feeding as “exactly” as possible

In case of high prices, the feed raw materials should be used as responsibly as possible:

- Protein and energy content (but also other components, such as minerals and vitamins) must meet the requirements of the animals – age and production phase are decisive for the calculations.

- Given variations in raw material quality, it is important to exactly determine nutrient contents to avoid over- and under-supply. For this purpose, technologies like the near-infrared spectroscopy (NIR) can be used.

Using locally available sources

In the initial stages of price hikes, it is often possible to resort to locally available sources, e.g., using sunflower or flaxseed meal to replace soybeans. Unfortunately, with increasing demand, these feed materials will usually become more expensive as well, and might not be suitable alternatives anymore. In general, however, it is worth using a maximum of local ingredients: they are often cheaper and less susceptible to transport and trade difficulties.

Feed additive solutions: use what is available in the best possible way

Once these first measures are exhausted, it is time to draw on industry solutions to derive maximum value out of the available feed ingredients. Let us consider four approaches that improve feed conversion and feed quality, adjust feed composition, and optimize feed production processes.

1. A critical goal: improving the feed conversion rate

The most direct way to better utilize feed is to improve the animals’ feed conversion rate, with the help of the right supplements. Different product groups contribute to this aim in different ways.

1.1 Phytomolecules fight on different fronts

Phytomolecules are well-known for their antimicrobial effects against pathogenic bacteria (Zhai et al., 2018). Phytomolecules shift the balance of the microbiome towards the beneficial side (eubiosis instead of dysbiosis) and promote gut health. A healthy gut is able to digest the feed and absorb the nutrients in an efficient way.

Another value of phytomolecules is their digestive effect. They stimulate the secretion of saliva, gastric juice and digestive enzymes, and favor an adequate gastrointestinal motility, which leads to improved nutrient utilization (Jones, 2001; Mendel et al., 2017).

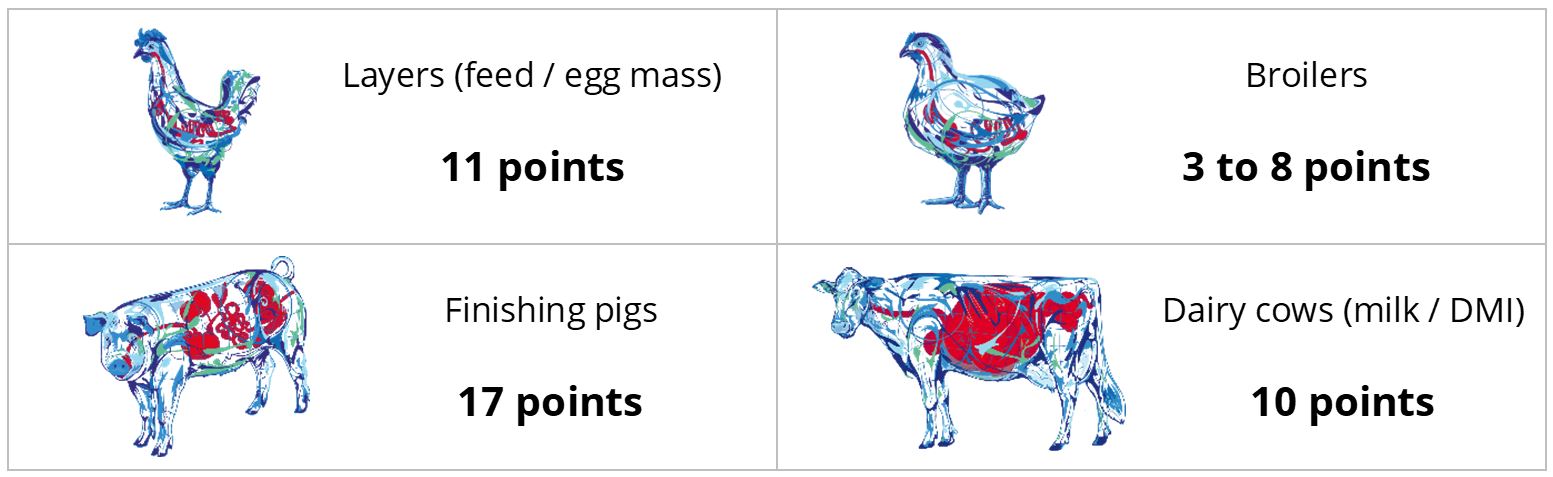

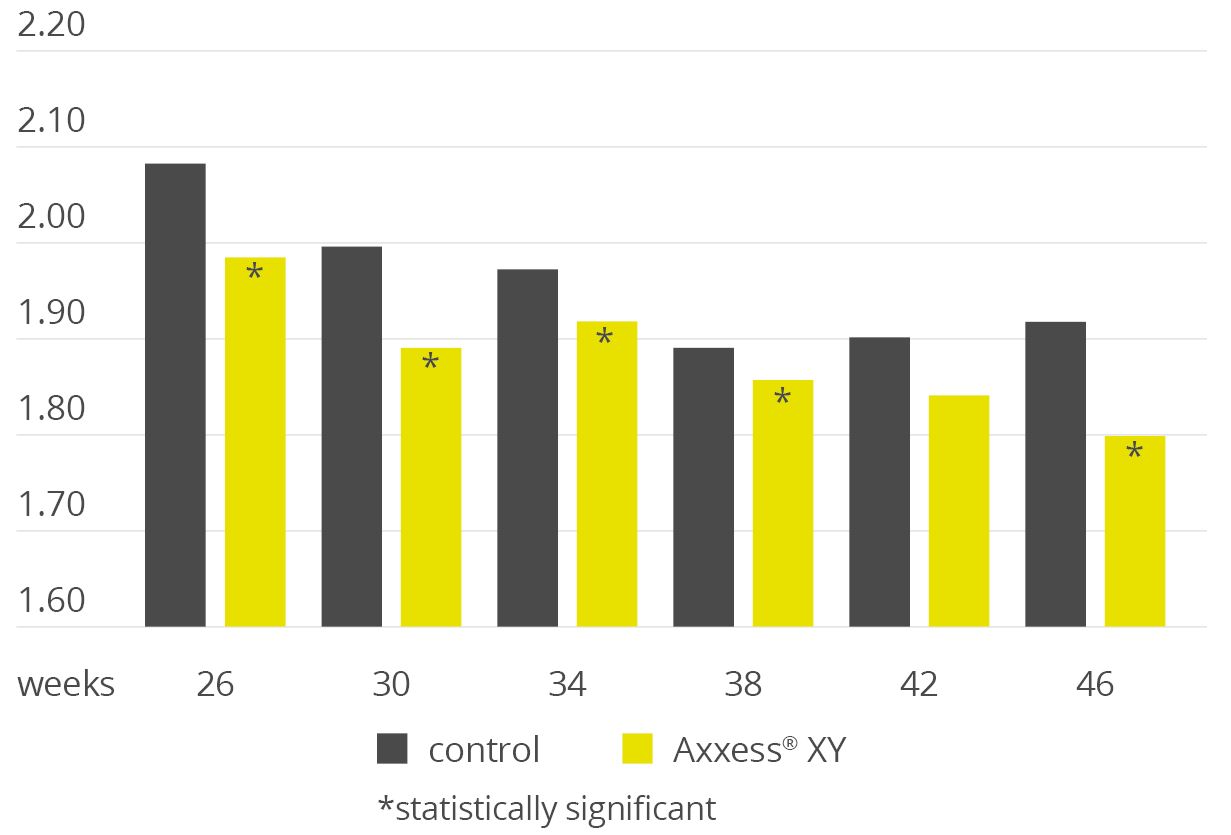

In trials testing the phytogenic Activo product range, supplemented animals showed the following FCR improvements compared to non-supplemented control groups (Figure 1):

Figure 1: FCR improvements for animals receiving Activo

1. 2 Enzymes improve nutrient availability

Even a corn-soybean meal diet is not fully digestible for monogastric animals. However, when feed prices increases, producers likely need to include more alternative ingredients in the diet that are much less digestible. Typically, these ingredients are rich in antinutritional factors such as non-starch polysaccharides (NSPs), which can cause detrimental effects on gut health.

Another disadvantage of NSPs is their “cage effect”. The water-insoluble NSPs cellulose and hemicellulose trap nutrients such as proteins and digestible carbohydrates. Consequently, digestive enzymes cannot reach them and they are not available to the organism.

Here is the point of attack for enzymes that enable a complete nutrient utilization: Making these substances available for the animals increases the energy content of the diet and, in the end, improves FCR. An example for laying hens receiving wheat-based diets can be found in Figure 2: Axxess XY, a xylanase, significantly improved feed utilization by the hens.

Figure 2: FCR in layers receiving Axxess XY, compared to control group (kg feed / kg egg mass)

1.3 Antioxidants maintain energy content of the diet

Corn Distiller’s Dried Grains with Solubles (DDGS), a by-product of corn distillation processes, are used as an alternative to corn. In DDGS, the starch content is removed, but fat is concentrated, reaching about three times the fat level of corn. This is the reason why the energy content in DDGS and corn is similar. This makes DDGS an attractive ingredient for monogastric diets; however, fat, especially at hot temperatures in the summer, can be oxidized. The resulting rancidity and the accompanying destruction of vitamins, pigments, and amino acid leads to a decrease in the diet’s bioavailability and energy content and to poor feed conversion.

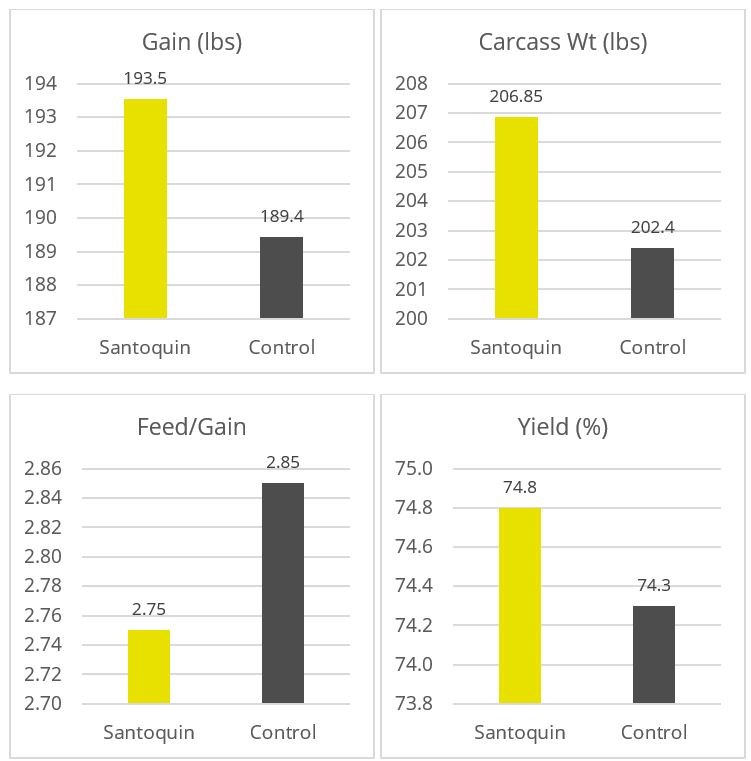

The use of antioxidants can stabilize DDGS and other fatty ingredients in the feed, maintaining nutrient integrity and availability. Figure 3 shows the performance benefits of using antioxidant product Santoquin in pork finisher diets in the USA containing 30% of DDGS.

Figure 3: Performance results for pigs receiving Santoquin (trial with Midwest pork producer)

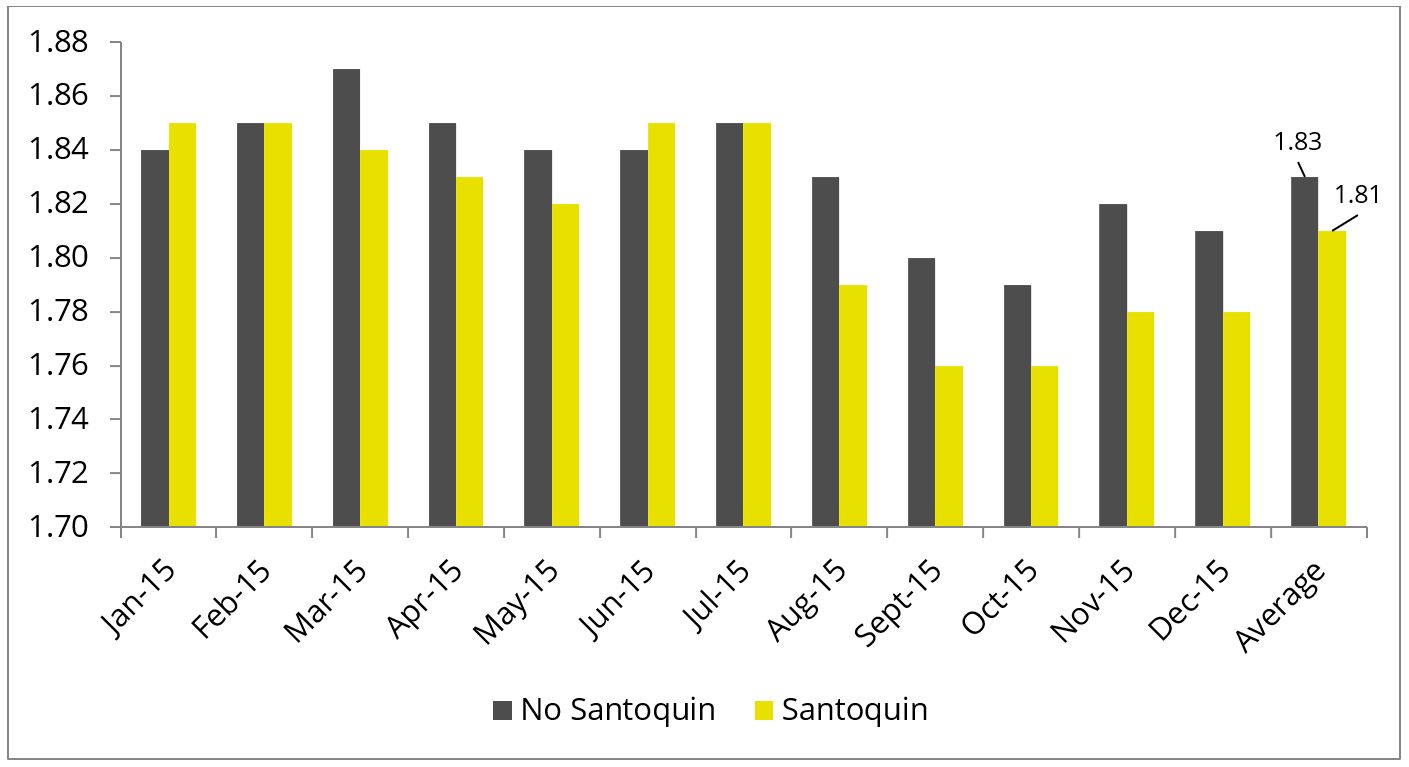

In poultry production, the use of DDGS is not as common as in swine. Antioxidants, however, can still help to protect the nutrients, maintain the energy content and improving FCR. The results from an extensive 2015 field study for broilers fed a diet without DDGS (shown in Figure 4) showed a net ROI of 6.7 to 1.

Figure 4: FCR in broilers receiving Santoquin, compared to non-supplemented control group

1.4 Organic acids improve intestinal processes

Organic acids, or acidifiers, can improve the gut microbiome, feed utilization, and gut health in production animals. The gut microbiome balance is aided by lowering the population of pathogenic bacteria susceptible to low pH, such as E. coli, Salmonella, and Clostridium.

Organic acids also directly attack pathogens by entering bacterial cells and changing the internal pH. Commensal bacteria such as Lactobacilli and Bifidobacteria survive as they can tolerate lower pH conditions. As pathogens constitute nutrient competitors, eliminating them improves gut health, which, is the most important precondition for optimal nutrient utilization.

The acidifying effect of organic acids furthermore favors digestion and nutrient utilization: for example, for weaned piglets that not able to produce enough HCl in the stomach, a low stomach pH is important for the activation of the proteolytic enzyme pepsin. Besides a non-optimal use of nutrients, undigested protein arriving in the intestine leads to the proliferation of undesired pathogens, decreasing health and performance.

Organic acids, therefore, improve FCR directly, by promoting nutrient utilization through the stimulation of enzymes, and indirectly, by enhancing gut health.

2. Improving feed quality

Feed quality is not only a question of raw material quality. Feed additives play an important role in ensuring feed safety and enabling optimal utilization by the animal.

2.1 Mold inhibitors preserve the feed’s value

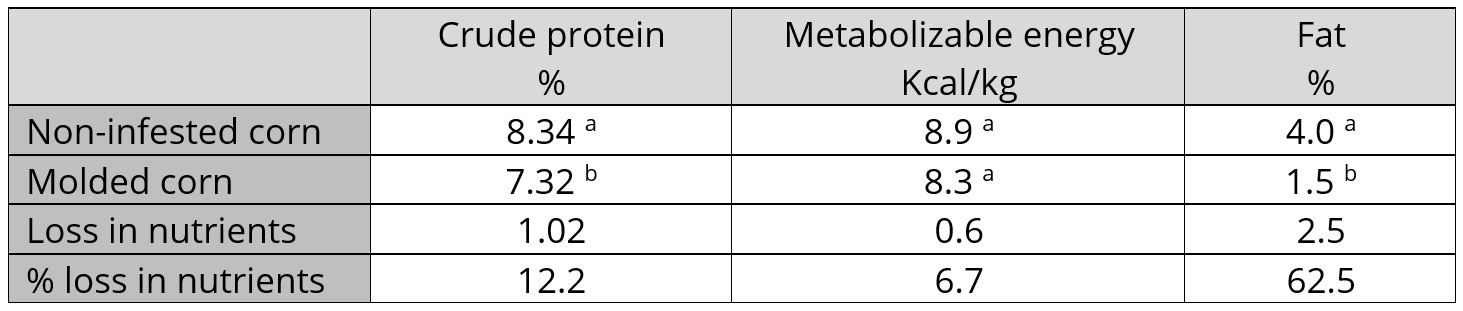

Molds reduce the nutrient and energy content of the feed (table 1) and have a negative impact on animals’ growth performance (table 2). Active water is the crucial point for mold growth. Compared to bacteria, which need about 0.90 – 0.97 Aw (active water), most molds require only 0.86 Aw.

Mold inhibitors contain different ingredients. Surfactants bind the free water, so that the moisture of the feed persists, but the active water important for molds is reduced. Organic acids, as already mentioned before, have antifungal properties. Together, they reduce molds and prevent the degradation of energy in the feed.

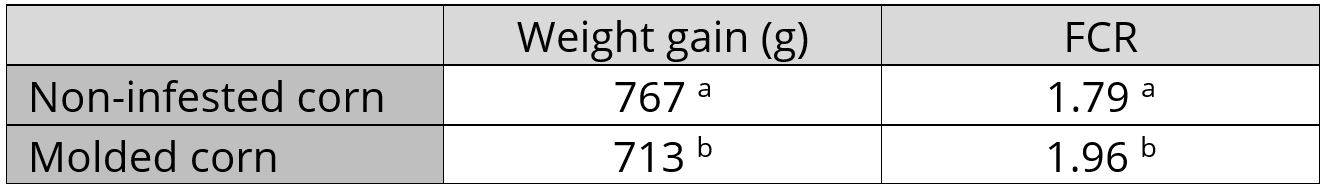

Table 1: Nutrient loss in corn infested with molds

Table 2: Comparison of 28-day-old chicks performance fed not-infested and molded corn

2.2 Mitigating the negative impact of mycotoxins

Mycotoxins contamination of grains can occur in the field, during raw material harvesting, transportation, storage, handling, and even during feed processing and storage. By mitigating the negative effects of mycotoxins – such as gut and liver inflammation, kidney degeneration or reproductive disorders – the animals’ health and performance can be maintained. In today’s contamination scenarios, it is absolutely necessary to use products that adsorb mycotoxins and contain their harmful impact on animals.

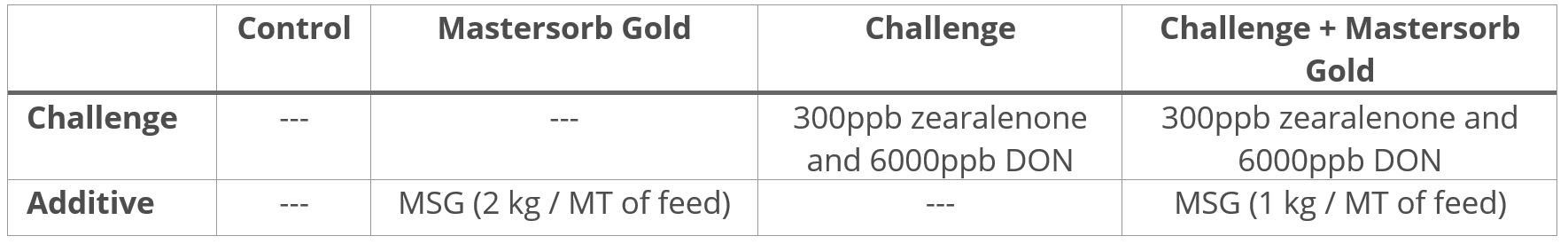

The effectivity of such products in animals is crucial. Table 3 shows an optimal experimental design and Figure 5 shows the results of its application: a total recovery of the performance pays off.

Table 3: Trial design, impact of Mastersorb Gold on broilers challenged with zearalenone and DON-contaminated feed

Figure 5: Average FCR for broilers, with or without zearalenone and DON challenge, with or without Mastersorb Gold supplementation

2.3 Surfactants for microbiological control and high pellet quality in the feed mill

Moisture is important. Too dry feed results in poor palatability and digestibility, and lower pellet quality. Also moisture loss has a direct impact on production and profitability.

The use of surfactants, makes it possible to bind the moisture to the feed, reaching a larger contact surface between water and feed particles, and improving starch gelatinization and pelleting efficiency. The improvement in starch gelatinization leads to a higher pellet quality, a lower proportion of fines and a higher content of metabolizable energy.

Moreover, moist steam has a better antimicrobial effect than dry steam, leading to lower fungal and bacterial growth and preventing the production of toxins. The pelleting temperature can also be lower, protecting the nutrients.

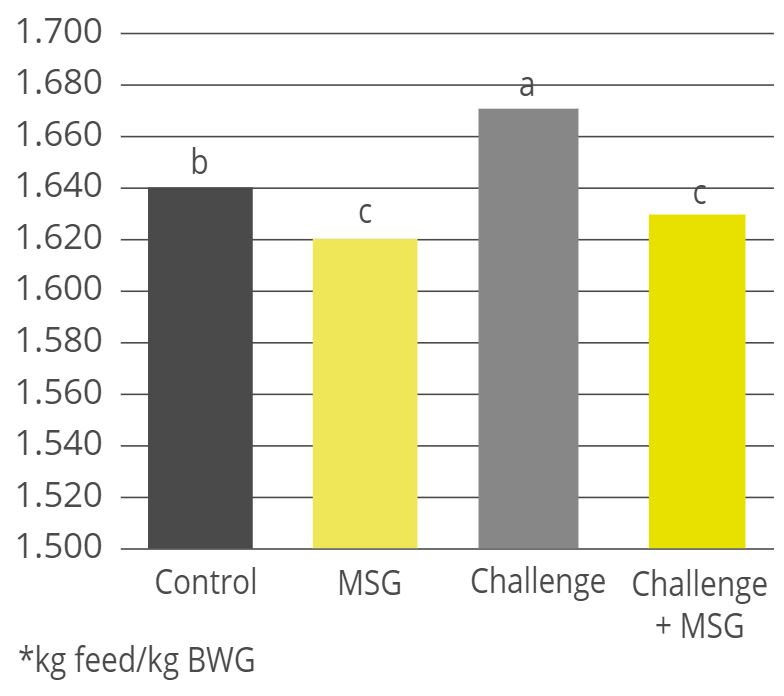

Figure 6 shows how the use of SURF•ACE, a synergistic blend of organic acids and surfactants, improves pellet durability, moisture content, and mold occurrence for beef and poultry pellet feed.

Figure 6: Improvements in pellet durability, moisture content and mold through using SURF•ACE

3. Using feed alternatives in ruminants – partial replacement of protein feed by urea

Ruminal bacteria are able to synthesize amino acids and, subsequently, generate a high-quality protein out of acid amides, a group of non-proteins occurring during the synthesis and degradation of proteins. What they require to do this is enough energy, minerals, and trace elements available in the feed (Weiß et al., 2011). When the bacteria arrive in the abomasum and in the small intestine they, or rather their proteins, are degraded by enzymes together with the undegradable rumen protein into useful amino acids.

With the aid of ruminal microbes, ruminants therefore partly cover their protein requirement through non-protein nitrogen. The most well-known is urea. It is critical that the urea given to animals has a degradation rate similar to other energy sources the animal consumes. Otherwise, there will be an imbalance between the quantity of usable nitrogen and the energy required for microbial protein synthesis: The urea accumulates in the rumen, becoming toxic for the microbiota and creating metabolic disorders.

Special coating technology allows for nitrogen to be released at a rate close to that of protein degradation of the main vegetable protein sources (e.g., soybean meal). This leads to a more constant nitrogen supply for the microorganisms and results in maximal synthesis of microbial protein.

4. Save costs in the production process

Besides high pellet quality, feed millers seek to maximize production efficiency. Factors contributing to this target are the amount of fines to be reprocessed, the utilization of steam, the pellet throughput and the energy demand. Once more, the moisture of the feed is of decisive importance. Substances can be added to the feed to achieve an optimal moisture content. These substances bind free water by generating an emulsion of dietary fat and the added water.

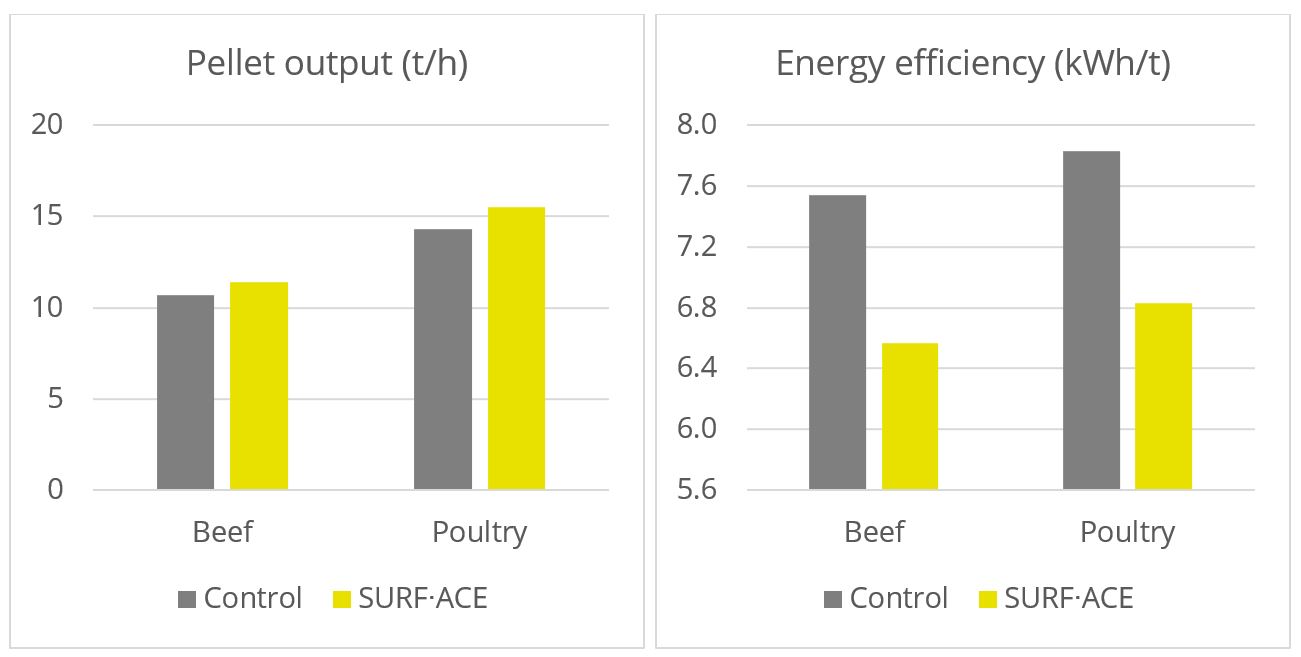

Besides the positive effects on pellet durability, moisture content and mold growth shown above, this leads to a better general lubrication of the machinery: The addition of feed mill processing aid SURF•ACE leads to a 10-15 % lower energy demand or a higher production output without increasing energy consumption (Figure 7), depending on the mill’s requirements. Good machinery lubrication additionally reduces wear and tear, another important dimension of production efficiency

Figure 7: Improvements in pellet output and energy efficiency through using SURF•ACE

Producers can rise to the challenge of rising feed prices

Rising feed costs pose a significant challenge to everyone in animal production. We are all compelled to look for alternatives to optimize the utilization of resources. This firstly involves a critical look at the efficiency of every step in our operations, but also includes utilizing targeted feed additives. Various measures are available for animal producers to optimize feed conversion, improve feed quality, and resort to alternative ingredients. In feed production, tools are on hand to optimize the manufacturing processes, improve feed quality, and make a positive impact on animal performance. Feed price fluctuations will continue to challenge our industry. Still, while tackling short- and medium-term difficulties, we can also strategically build resilience – and take the measures today that will contribute to our long-term ambitions for sustainable and profitable production.

References

Jones, G. “Leistungsstarke Tiere und Verbraucherschutz stehen nicht im Widerspruch – Wirkung eines phytogenen Zusatzstoffs / High-performing livestock and consumer protection are not contradictory – Impact of a phytogenic additive.” Kraftfutter/ Feed Magazine 12 (2001): 468-473.

Mendel, M., Chłopecka, M., Dziekan, N., & Karlik, W. (2017). Phytogenic feed additives as potential gut contractility modifiers—A review. Animal Feed Science and Technology, 230, 30–46. https://doi.org/10.1016/j.anifeedsci.2017.05.008.

Weiß, J.W., S. Granz, W. Pabst. Tierproduktion. Thieme Verlag (2005):155-159.

Zhai, Hengxiao, Hong Liu, Shikui Wang, Jinlong Wu, and Anna-Maria Kluenter. “Potential of Essential Oils for Poultry and Pigs.” Animal Nutrition 4, no. 2 (June 2018): 179–86. https://doi.org/10.1016/j.aninu.2018.01.005.